The printing industry is evolving fast, and sustainability isn’t just a buzzword—it’s a survival strategy. With growing pressure to reduce waste and embrace circular economy principles, technologies like LED UV curing are stepping into the spotlight. Let’s break down how LED UV intersects with recyclability in key printing processes like label, flexo, offset, and narrow-web printing.

Why LED UV Curing Fits the Circular Economy

Traditional printing often relies on solvent-based inks or mercury-arc UV systems, which leave behind volatile organic compounds (VOCs) or hazardous waste. LED UV, by contrast, uses instant light energy to cure inks and coatings without heat or emissions. This means:

- Less energy waste: LED systems consume 60–70% less power than conventional UV setups.

- No toxic residues: Inks cure fully, eliminating VOC release and making printed materials easier to recycle.

- Longer lifespan: LED lamps last 20,000 hours vs. 1,000–2,000 hours for mercury bulbs, reducing hardware waste.

For recyclability, this matters. Contaminants from solvents or uncured inks can derail recycling processes. LED UV ensures prints stay “clean” from start to end-of-life.

Label Printing: Thin Films, Big Sustainability Wins

Labels face strict recyclability demands—especially in food/beverage packaging. PET bottles with PVC labels, for example, often get rejected by recycling plants. LED UV enables:

- Thinner ink layers: Precise curing allows minimal ink use, reducing material complexity.

- Compatibility with mono-materials: Water-based LED UV inks adhere well to PP/PE films, supporting single-material packaging designs.

- No adhesive interference: Unlike heat-cured inks, LED UV doesn’t weaken label adhesives, preventing detachment during recycling.

Pro tip: Pair LED UV with wash-off adhesives to ensure labels separate cleanly during bottle recycling.

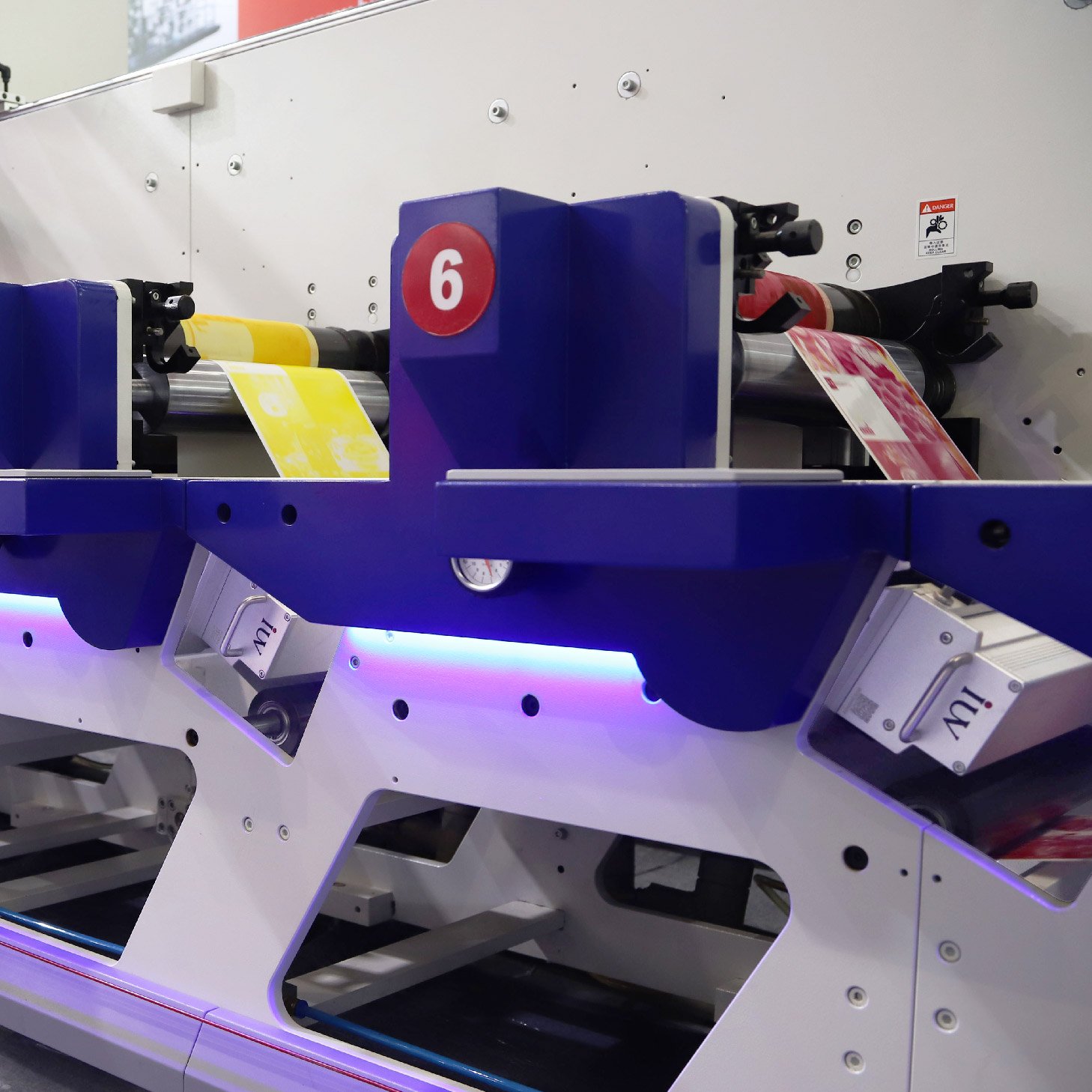

Flexo Printing: Speed Meets Substrate Flexibility

Flexo’s strength lies in handling diverse substrates—films, papers, foils. But traditional flexo inks can complicate recycling due to pigment migration or slow curing. LED UV fixes this by:

- Instant curing on low-thermal substrates: Print on heat-sensitive materials (e.g., shrink sleeves) without warping.

- Reducing ink bleed: Crisp dots and sharp colors mean less ink is needed to achieve opacity.

- Enabling water-washable plates: LED UV’s cold process keeps photopolymer plates stable, extending their life.

Case in point: A European label converter cut its flexo ink waste by 40% after switching to LED UV, citing better ink transfer and fewer press stops.

Offset Printing: Cutting Chemistry, Boosting Recycled Content

Offset isn’t going extinct—it’s adapting. LED UV hybrid presses (like Komori’s H-UV) combine offset’s quality with UV’s eco-benefits:

- Eliminating powder spray: LED-cured sheets don’t need anti-setoff powder, which contaminates recycled paper fibers.

- Compatibility with recycled paper: UV coatings strengthen low-quality sheets, allowing higher recycled content without jamming presses.

- Faster turnaround: Prints are ready for binding or cutting immediately, slashing energy-intensive drying steps.

Fun fact: A study by Paper Recycling International found UV-coated papers have a 92% recycling yield vs. 78% for solvent-varnished sheets.

Narrow-Web Printing: Small Runs, Big Environmental Impact

Narrow-web’s niche—short runs for labels, tags, and flexible packaging—is where LED UV shines brightest:

- Reduced make-ready waste: Instant curing lets presses achieve color accuracy faster, saving substrate.

- No ozone emissions: Unlike conventional UV, LED systems don’t require exhaust systems, simplifying workspace safety.

- Hybrid printing capabilities: Combine digital toner with LED UV varnish for variable-data prints that are still recyclable.

Designing for Recyclability: A Checklist for Printers

To align with circular economy goals, use LED UV alongside these practices:

- Simplify material stacks: Avoid mixing PET with PE layers; opt for mono-material designs.

- Choose UV inks wisely: Opt for formulations free of photoinitiators like ITX, which can hinder recycling.

- Collaborate early: Work with recyclers and brands to test print waste in recycling streams.

Final Word

LED UV isn’t just a tech upgrade—it’s a bridge to circularity. By cutting energy, eliminating toxins, and keeping materials pure, it lets printers meet sustainability targets without sacrificing quality. As recycling infrastructure grows, those who design for recyclability today will own the market tomorrow.

Need help integrating LED UV into your workflow? Drop your questions below—let’s troubleshoot like engineers.