The packaging industry thrives on speed, precision, and durability. Enter UV curing—a game-changer for labels, flexible packaging, and narrow-web applications. But how does instant UV curing work, and why does it dominate modern printing? Let’s break down the chemistry, machinery, and real-world impact of this tech.

The Physics of UV Curing: Light, Chemistry, and Speed

UV curing uses light to transform liquid inks or coatings into solid polymers in seconds. Unlike traditional drying methods, which rely on evaporation, UV lamps (or LEDs) trigger a photochemical reaction. Here’s the kicker:

- Photoinitiators in the ink absorb UV light, generating free radicals.

- These radicals kickstart polymerization, linking molecules into a rigid chain.

- The result? Instant curing with zero solvent emissions.

For flexographic or offset printing, this means no waiting for inks to dry. Labels stay smudge-free, and presses run faster.

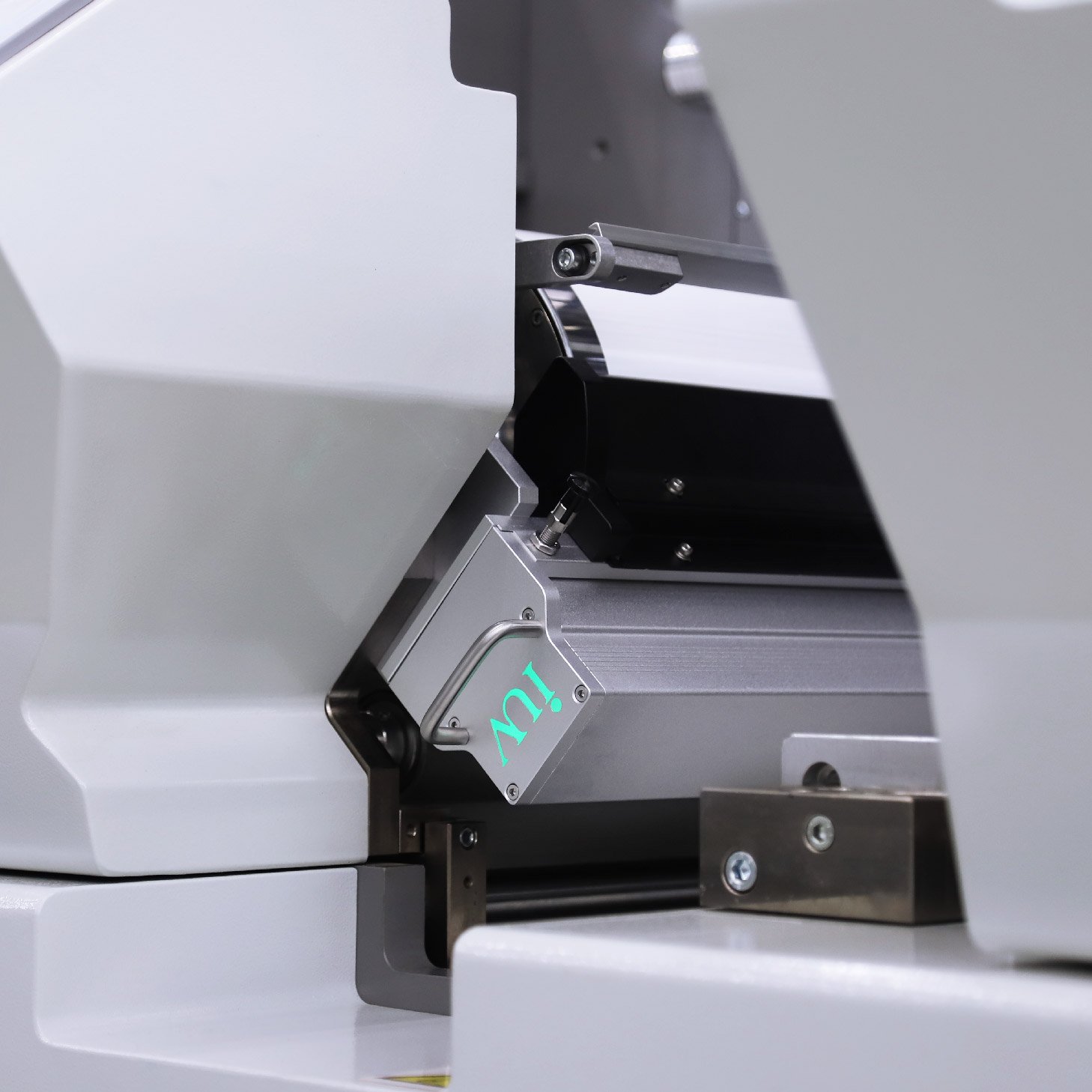

LED vs. Mercury Arc Lamps: Why LEDs Are Winning

Older UV systems used mercury-vapor lamps. They worked, but had drawbacks:

- High heat output (risky for heat-sensitive films)

- Short lamp life (1,000–2,000 hours)

- Toxic mercury disposal

LED UV systems flipped the script:

- Cool operation: Ideal for thin films in narrow-web printing.

- Energy efficiency: 70% less power than mercury lamps.

- Longevity: 20,000 hours of use.

In label printing, LEDs let converters handle PET, PP, and even heat-sensitive substrates without distortion.

UV Curing in Action: Flexo, Offset, and Narrow-Web

Flexographic Printing

Flexo dominates labels and flexible packaging. UV curing here eliminates dot gain issues—wet ink doesn’t spread, so fine text and barcodes stay crisp. Bonus: Water-based UV inks reduce VOC emissions by 95% compared to solvent-based alternatives.

Offset Printing (Sheetfed)

UV offset excels in premium packaging. Imagine a cosmetic box with raised textures and metallic inks. UV curing locks these effects in place instantly, enabling complex layering without smudging.

Narrow-Web Printing

Think pressure-sensitive labels or shrink sleeves. UV systems here pair with rotary presses for speeds up to 300 meters/minute. LED-UV’s low heat is a lifesaver for stretchy films like PVC or OPP.

The Sustainability Angle

UV curing isn’t just fast—it’s green.

- Zero VOCs: No solvents mean safer workplaces and cleaner air.

- Energy savings: LED systems cut power use by half.

- Less waste: Instant curing reduces misprints and substrate warping.

A 2022 study found UV-cured labels reduced carbon footprints by 40% compared to solvent-based options.

Challenges (and Fixes)

UV tech isn’t flawless. Common gripes:

- Substrate limitations: Some materials yellow under UV light.

Fix: Use UV stabilizers or switch to LED systems with narrower wavelength control. - Ink costs: UV inks are pricier than conventional ones.

Fix: Factor in reduced energy and waste costs—ROI often hits 12–18 months. - Adhesion issues: Non-porous substrates like glass or metal foil can be tricky.

Fix: Plasma treatment pre-printing boosts surface energy for better ink grip.

The Future: What’s Next for UV Curing?

- Hybrid systems: Combining UV with electron beam (EB) curing for 3D effects.

- Bio-based photoinitiators: Reducing reliance on petrochemicals.

- Smart curing sensors: AI-driven systems adjusting UV intensity in real time.

Final Word

Instant UV curing isn’t magic—it’s science. For converters in labels, flexible packaging, or narrow-web, adopting UV tech means faster turnarounds, sharper prints, and a smaller environmental footprint. Still on the fence? Ask yourself: Can your workflow afford to wait for ink to dry?