When it comes to printing, understanding the differences between flexographic printing and offset printing can help you make informed decisions for your projects. Each method has its own strengths, weaknesses, and ideal applications. In this article, we’ll explore the key differences between these two printing techniques to help you determine which one is best suited for your needs.

1. Printing Plates

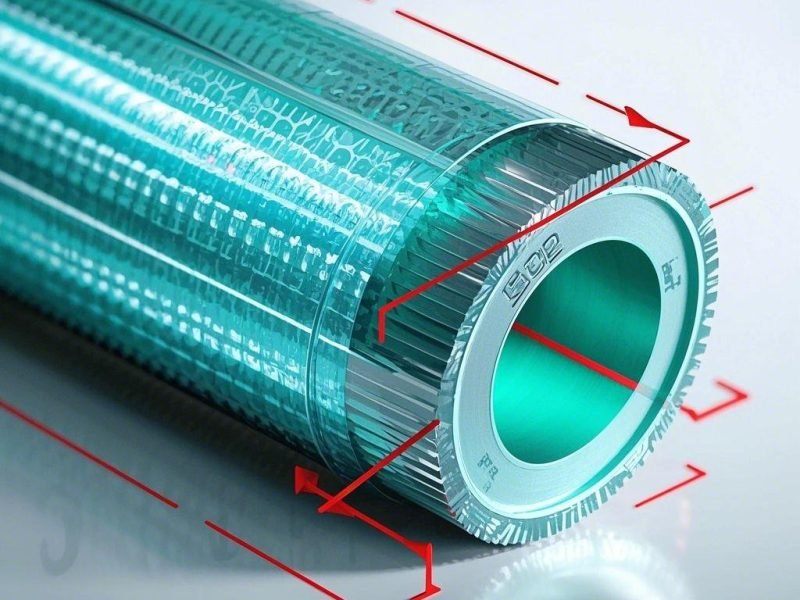

Flexographic Printing

Flexographic printing utilizes flexible photopolymer or rubber plates that are wrapped around rotating cylinders. These plates have a raised image that gets inked and transferred directly onto the material. The flexibility of these plates allows for printing on a variety of surfaces, from absorbent to non-absorbent materials. For each color, a separate plate is used, with every plate mounted on its own printing station. Flexo plates are highly durable and can be reused multiple times if stored properly.

Offset Printing

Offset printing involves transferring ink from a plate to a rubber blanket before it’s applied to the substrate. The plates used in offset printing are typically made of aluminum and can be utilized in both flat-bed and rotary presses depending on the setup. This “offset” process gives the method its name. The plates are usually flat and require a smooth surface for optimal results.

2. Ink Systems

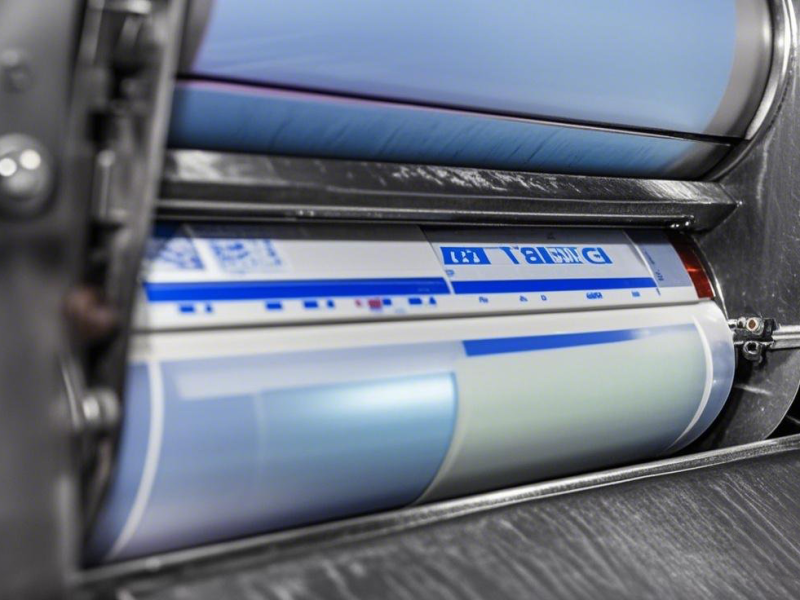

Flexographic Printing

Flexo printing uses a variety of ink types including water-based, solvent-based, and UV-curable inks. These inks dry quickly, making them suitable for high-speed production. UV-curable inks are particularly advantageous as they can remain in the press without needing to be cleaned out at the end of a shift. However, water-based inks require careful removal and cleaning to prevent drying on the rollers and trays, which could cause clogging.

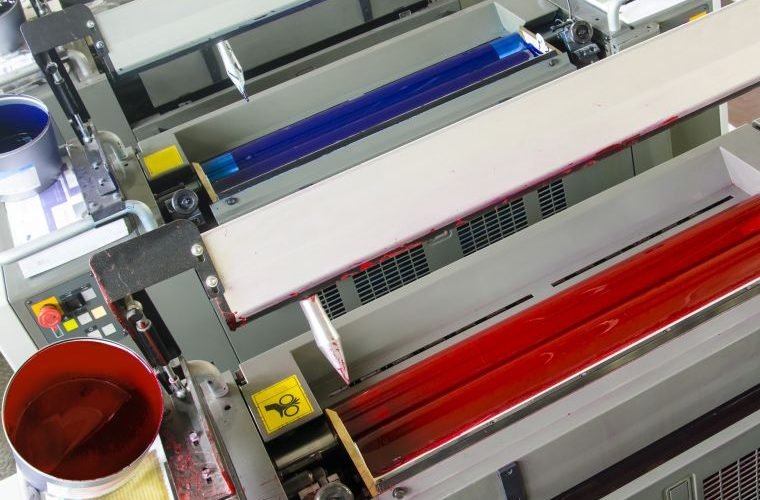

Offset Printing

Offset printing primarily uses oil-based or UV inks. While these inks produce vibrant, high-quality results, they often require longer drying times, especially for water-based inks. The ink system in offset printing is based on the CMYK color model—cyan, magenta, yellow, and black—with each color having its own printing station. Spot colors can also be mixed from these four standard process colors.

3. Materials and Substrates

Flexographic Printing

Flexographic printing excels in its versatility of materials. It can print on both absorbent and non-absorbent surfaces, including plastic, foil, fabric, metal, cellophane, and cardboard. This makes it ideal for packaging applications such as labels, envelopes, retail bags, wallpaper, and food wrappers. Many flexo presses come with built-in finishing options like die-cutting or laminating, enabling the entire process to be completed in a single pass.

Offset Printing

Offset printing is best suited for smooth, flat surfaces such as paper, cardboard, metal, vinyl, and cellophane. It’s commonly used for producing high-quality products like magazines, books, brochures, posters, and newspapers. Offset presses usually require a second pass for double-sided printing, and additional finishing processes like folding, die-cutting, laminating, or creasing are often done separately after the initial print run.

4. Setup Costs

Flexographic Printing

Flexography often involves higher initial costs due to the need for custom plates and complex machine preparation. This investment can be justified for extensive production runs where the plates offer long-term use.

Offset Printing

Offset lithography usually has lower upfront costs. The process to prepare plates and equipment is more straightforward and economical, making it suitable for smaller-scale projects or initial print runs.

5. Run Length

Flexographic Printing

Flexographic printing is designed for high-speed production, making it ideal for large-scale tasks such as packaging and labels. It can operate at speeds of up to 2,000 linear feet per minute (fpm), ensuring efficiency and cost-effectiveness for extensive print jobs.

Offset Printing

Offset printing is also suited for large volumes, with presses capable of handling up to 18,000 sheets per hour, or 300 sheets per minute. While setup may be more time-consuming, offset printing offers excellent consistency and quality for high-volume projects requiring detailed graphics.

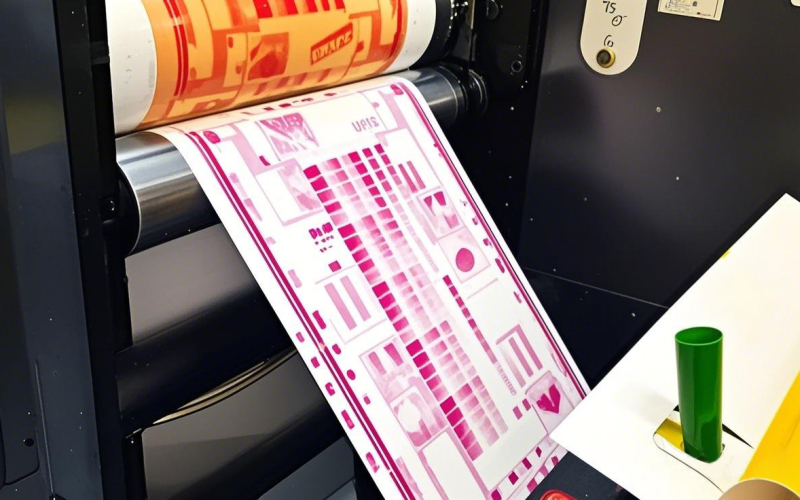

6. Print Quality

Flexographic Printing

Flexographic printing produces reliable results across various surfaces. It’s adept at producing clear and consistent prints, especially useful for packaging and flexible materials. While quality has improved over the years, it may not match offset printing in terms of fine detail reproduction.

Offset Printing

Offset printing excels in producing high-resolution images with vivid colors. This method is preferred for projects requiring detailed graphics and rich, accurate hues, such as magazines, packaging, and premium brochures. The transfer process via a rubber blanket allows for sharp images and fine details.

7. Maintenance

Flexographic Printing

Flexographic printing demands more frequent maintenance. Regular cleaning of the plates and ink systems is necessary, especially with water-based inks that can dry and cause blockages. However, the plates are durable and can be reused multiple times.

Offset Printing

Offset printing requires less maintenance. Although regular cleaning is needed, the process is simpler, leading to easier long-term care and reduced maintenance efforts. The plates used in offset printing are typically more rigid and require periodic replacement.

8. Environmental Impact

Flexographic Printing

Flexographic printing is generally considered more eco-friendly. It uses less ink and energy, and many presses have multiple converting options integrated into the press, enabling a single pass operation. This efficiency reduces waste and environmental impact.

Offset Printing

Offset printing can produce waste, particularly due to the chemicals used in plate-making and traditional inks that contain solvents and volatile organic compounds (VOCs). However, many offset printers are shifting to eco-friendly practices, such as using vegetable-based inks and recycling, to reduce their environmental impact.

Conclusion