In narrow web flexographic label printing, curing consistency is a direct driver of print quality, press efficiency, and downstream performance. As LED UV curing becomes the dominant technology, many converters discover that stable irradiance alone does not guarantee reliable results. UV dose, defined as the total energy delivered to the ink or coating, is the parameter that determines whether curing is complete and repeatable. Radiometers are the primary tools that allow press operators and engineers to measure, control, and standardize LED UV dose across jobs, speeds, and press configurations.

Understanding UV Dose in LED UV Flexo Printing

UV dose is the product of irradiance and exposure time. In LED UV flexo printing, irradiance is determined by lamp output, optics, and distance to the substrate, while exposure time is governed by press speed and lamp footprint. Unlike mercury lamps, LED UV systems emit narrow-band energy with minimal infrared heat. This makes dose control more precise but also more sensitive to process variation. A small change in speed or lamp output can shift dose outside the curing window, leading to adhesion issues or overcured ink films.

Why Irradiance Alone Is Not Enough

Many production teams focus on peak irradiance values when evaluating LED UV performance. While irradiance influences surface cure speed, it does not describe how much total energy the ink receives. Two presses can show identical irradiance readings yet deliver very different doses due to speed differences or lamp geometry. In narrow web flexo, where ink film thickness and substrate type vary widely, dose consistency is the parameter that correlates most strongly with curing reliability.

The Role of Radiometers in LED UV Process Control

Radiometers translate UV energy into measurable data. In LED UV applications, modern radiometers are designed to match specific wavelength ranges, typically 365 nm, 385 nm, or 395 nm. These instruments measure irradiance and calculate dose at the substrate level, providing objective feedback on curing conditions. Without radiometric data, LED UV curing becomes a subjective process based on visual inspection rather than controlled engineering parameters.

Selecting the Right Radiometer for Narrow Web Presses

Not all radiometers are suitable for LED UV curing. Narrow web presses require compact sensors that can pass safely through the press path without disturbing web tension. The radiometer must be spectrally matched to the LED wavelength used on press. A mismatch between sensor sensitivity and lamp output produces misleading readings. Selecting the correct radiometer ensures that measured values reflect actual curing conditions experienced by the ink.

Establishing Baseline Dose Values

Before dose can be controlled, a baseline must be established. This involves measuring UV dose under known good printing conditions where adhesion, rub resistance, and chemical resistance meet specifications. Baseline values should be recorded for each curing unit, wavelength, and typical press speed. These values become reference points for future setup and troubleshooting. In narrow web flexo operations, baselines often differ between paper labels, films, and specialty substrates.

Measuring Dose Across the Web Width

Uniform curing across the web is essential for consistent label quality. LED UV lamps rely on optical systems to distribute energy evenly, but alignment and aging can introduce variation. Radiometer measurements should be taken at multiple positions across the web width. Uneven dose distribution often explains edge curing failures or color variation that cannot be resolved through ink adjustments alone.

Press Speed Changes and Dose Stability

Press speed is one of the most influential variables in UV dose delivery. As speed increases, exposure time decreases. If lamp output is not adjusted accordingly, total dose drops. In LED UV flexo printing, this can result in inks that appear cured at the surface but fail adhesion tests. Radiometers allow operators to quantify how dose changes with speed and to define safe operating windows for different substrates and ink systems.

Synchronizing LED UV Output with Speed

Advanced LED UV systems can link output control to press speed. Radiometric data supports this synchronization by identifying the dose required at each speed. By maintaining a constant dose rather than constant irradiance, curing conditions remain stable during acceleration, deceleration, and job changeovers. This approach reduces waste and minimizes manual intervention by press operators.

Ink Film Thickness and Dose Requirements

Ink film thickness varies with anilox selection, color density, and print design. Thicker films require higher total dose to achieve full polymerization through the ink layer. Radiometer data helps correlate film thickness with dose demand. In narrow web flexo, this is especially important for opaque whites, tactile varnishes, and high-solids coatings. Without dose measurement, undercure at the ink-substrate interface may go unnoticed until converting failures occur.

Wavelength-Specific Dose Measurement

Different LED wavelengths interact with ink chemistry in distinct ways. Shorter wavelengths promote rapid surface cure, while longer wavelengths penetrate deeper into the ink film. Radiometers that capture wavelength-specific data help printers optimize curing strategies for different applications. Measuring dose at the correct wavelength ensures that photoinitiators are activated efficiently and consistently.

Diagnosing Curing-Related Print Defects

Many common print defects are symptoms of improper dose rather than mechanical issues. Poor adhesion, ink cracking, blocking during rewinding, and inconsistent gloss often trace back to dose variation. Radiometric measurement allows these problems to be diagnosed objectively. By comparing measured dose against baseline values, operators can determine whether the root cause is curing-related or process-related.

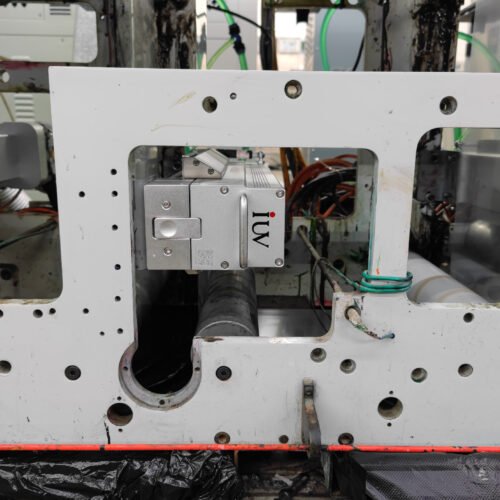

Radiometer Use During Commissioning and Retrofits

During press commissioning or LED UV retrofits, radiometers play a central role. Initial measurements verify that installed systems deliver the expected energy to the substrate. Adjustments to lamp height, optics, and output can be validated immediately through dose data. This shortens commissioning time and establishes confidence in the curing system from the first production run.

Routine Monitoring and Preventive Control

LED UV systems offer long service life, but output still changes over time due to component aging and thermal effects. Routine radiometric monitoring detects gradual dose drift before it affects print quality. Establishing regular measurement intervals transforms curing control from reactive troubleshooting to preventive process management.

Integrating Dose Control into Standard Operating Procedures

For consistent results, dose measurement should be part of standard operating procedures. Documented dose targets for each substrate and ink system enable fast and repeatable setups. Operators can verify curing conditions during job startup rather than relying on post-production testing. This integration reduces scrap and improves overall equipment effectiveness.

Training Operators to Interpret Radiometric Data

Radiometers provide data, but value comes from correct interpretation. Operators should understand the difference between irradiance and dose and how both relate to press speed and ink performance. Training ensures that radiometric readings lead to informed decisions rather than unnecessary adjustments that destabilize the process.

Building a Data-Driven LED UV Curing Strategy

Dose control transforms LED UV curing from an art into a measurable engineering process. Radiometric data creates a common language between press operators, ink suppliers, and equipment engineers. In narrow web flexo printing, this shared understanding supports continuous improvement and predictable quality across shifts and production sites.

Conclusion: Radiometers as the Foundation of LED UV Consistency

Consistent LED UV curing on narrow web flexo presses depends on accurate dose control rather than assumptions about lamp performance. Radiometers provide the practical means to measure, verify, and standardize curing energy. By embedding dose measurement into daily operations, converters achieve stable adhesion, reliable print quality, and efficient production across a wide range of label applications.