UV curing has become a foundation of modern label, narrow-web, flexo and offset production. This tutorial focuses on practical UV and LED curing knowledge for pressroom engineers and print technicians. Coverage includes photochemistry, lamp technology, substrate interactions, process control and common troubleshooting for label and narrow-web operations.

Fundamental principles of UV curing

UV curing converts liquid ink or coating into a solid film through rapid photopolymerization. Photoinitiators absorb UV photons and generate reactive species, typically free radicals or cations. These reactive species initiate polymer chain formation between oligomers and monomers in the ink matrix. Cure speed depends on light intensity, exposure time and ink formulation chemistry.

Key components in a UV system

- Light source: mercury arc lamps or UV LED arrays.

- Reflectors and optics: concentrate output onto the web.

- Cooling and ventilation: maintain lamp and substrate temperatures.

- Photoinitiators and resin systems: tuned to the spectral output.

- Measurement instruments: radiometers and spectroradiometers for dose control.

Photochemistry and ink formulation

Flexo and offset UV inks share common chemistry but differ in viscosity and transfer properties. Free-radical systems dominate for most flexo label inks due to fast cure and broad resin compatibility. Cationic chemistries appear in some coatings and specialty applications, offering lower oxygen inhibition and improved adhesion to certain substrates. Photoinitiator absorption must match lamp emission peaks; mismatches reduce cure efficiency.

Mercury lamp versus LED technologies

Traditional mercury arc lamps emit a broad UV spectrum with peaks near 254 nm, 313 nm, 365 nm and 405 nm. That broad emission supports many photoinitiators. Mercury lamps produce heat and ozone, and require warm-up and cooling cycles. UV LED sources emit a narrow band, typically between 365 nm and 420 nm, with the most common industrial arrays at 385 nm or 395 nm. Advantages of LED include instant on/off, lower heat load, no ozone generation, and longer operational life. Downsides include the need for ink photoinitiators optimized for the LED emission band and higher upfront retrofit costs.

Specifics for label printing and narrow-web flexo

Label printers commonly run on narrow-web flexo presses that process films and self-adhesive substrates. Films such as BOPP, PET and vinyl have low thermal tolerance and require minimized IR heat. LED curing is particularly valuable for these jobs because it reduces substrate distortion and adhesive degradation. UV flexo inks for labels must balance tack, rub resistance and adhesion to treated films. Proper corona or plasma treatment levels on film surfaces improve ink wetting and adhesion.

Offset (胶印) considerations with UV curing

Offset UV inks are formulated for transfer from plate to blanket to substrate. In UV offset, solvent-free UV inks eliminate long drying racks, enabling immediate finishing and die-cutting. Pressroom challenges include maintaining optimal blanket and roller chemistry, preventing set-off, and avoiding transfer of tacky ink to downstream equipment. Offset presses require careful ink-water balance when using UV varnishes or coatings, and operators must guard against emulsification during conventional offset printing followed by UV coatings.

Process control: energy, speed and dose

Cure is a function of irradiance (mW/cm²) and exposure time (seconds), often expressed as dose or energy (mJ/cm²). Higher web speeds reduce exposure time and demand greater irradiance or additional lamp modules. Typical label flexo jobs require doses tailored to ink and substrate; modern LED systems commonly deliver 200–1,200 mJ/cm² depending on chemistry. Use radiometers to monitor intensity and spectroradiometers for spectral fidelity. Control web tension and nip conditions to avoid ink smearing before full cure.

Substrate influence and adhesion strategies

Substrates differ in surface energy, heat sensitivity and optical properties. Films reflect and transmit UV differently than paper, changing effective cure. Additives in inks, such as adhesion promoters and specific oligomers, enhance bonding to low-energy plastics. Pre-treatment levels matter: target surface energy above substrate-specific thresholds to ensure durable adhesion. For pressure-sensitive adhesives, monitor adhesive softening that can occur with excessive heat or UV dose.

Common defects and troubleshooting

- Under-cure: tacky surface, blocking, poor chemical resistance. Check irradiance, exposure time and photoinitiator compatibility.

- Over-cure: yellowing, embrittlement, poor adhesion to coatings. Reduce dose or modify ink formulation.

- Pinholing and foam: trapped gases in ink or substrate outgassing during cure. Improve ink degassing and adjust dryer ventilation.

- Set-off and transfer: insufficient surface cure before contact. Increase initial lamp power or add chill rollers.

- Adhesion loss: improper substrate treatment or incompatible ink-resin chemistry. Verify surface energy and adhesion promoter use.

Measurement and quality assurance

Integrate inline and offline metrology. Radiometers provide quick intensity checks but lack spectral detail. Spectroradiometers measure emission spectra and identify wavelength shifts. Cure meters that measure tack or surface energy can validate process windows. Implement routine lamp checks, replace reflectors as they dull, and log dose readings per job to enable traceability.

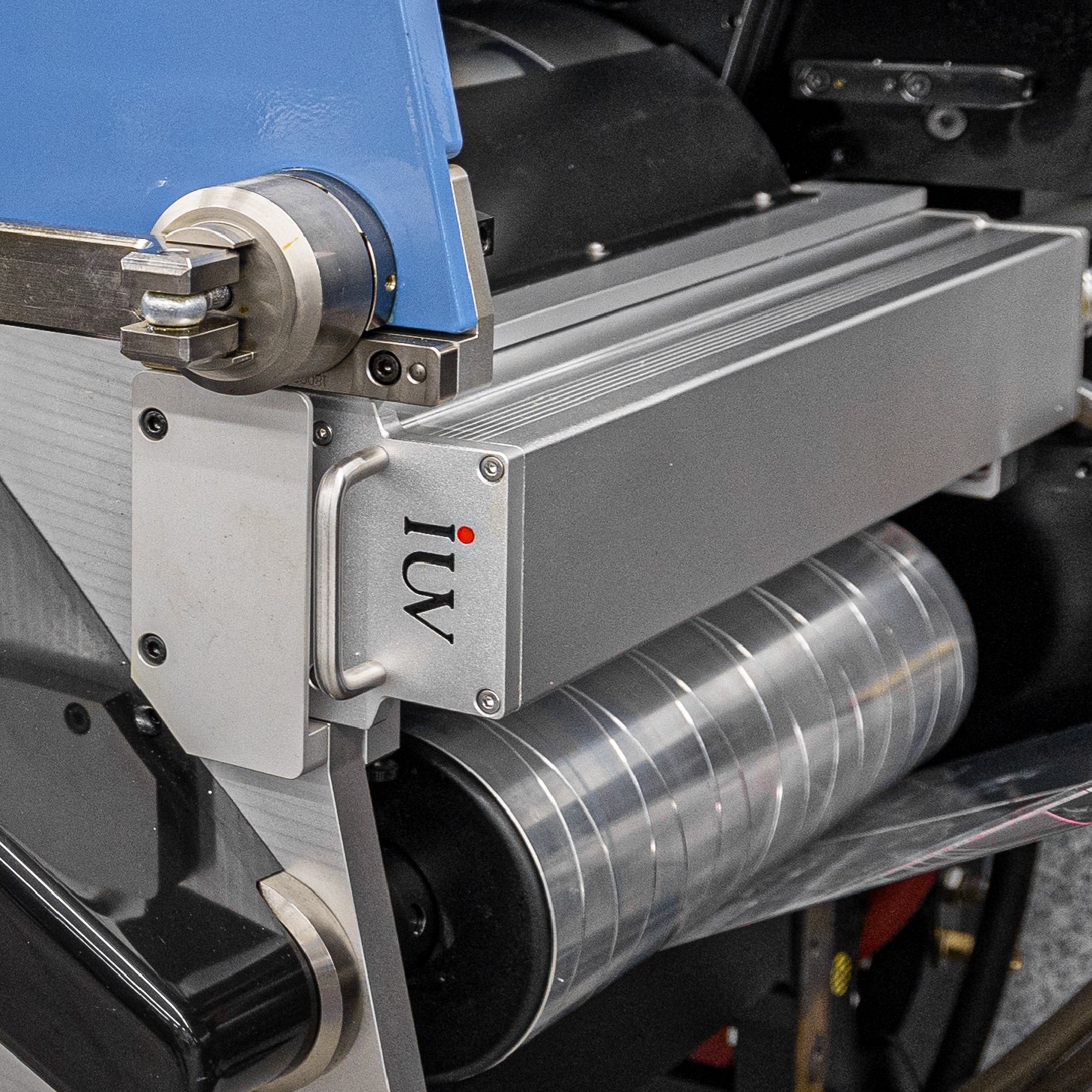

Retrofit and integration guidance

When retrofitting existing presses, evaluate web path, available clearance, cooling capacity and electrical supply. LED modules tend to be more compact but may require multiple arrays to match dose. Ensure mechanical mounts provide proper distance and angle to the web. Verify that press controls support variable speed matching to lamp dimming or staging. Work with ink and lamp manufacturers to validate chemistry compatibility before full production runs.

Maintenance and lifecycle considerations

Mercury lamps require periodic replacement and safe disposal due to hazardous materials. LED systems display gradual lumen depreciation rather than abrupt failure. Routine cleaning of lenses and reflectors prevents output loss. Maintain ventilation ducts clear of ink mist and debris. Track cumulative run hours for predictive maintenance planning and budget for eventual component replacement.

Safety and environmental aspects

UV exposure poses eye and skin hazards. Guarding, interlocks and protective windows are standard controls. Use shielding that blocks relevant UV bands. Ventilation must remove ozone when using mercury lamps and reduce airborne photoproducts. LED systems eliminate ozone generation and reduce energy consumption, lowering environmental impact and operational costs.

Optimizing recipes for production

Develop repeatable ink and curing recipes for each substrate. Record lamp settings, speed, ink batch, and pretreatment levels. Run adhesion and abrasion tests during setup. For multi-pass varnishes or opaque whites, stage cure energy across modules to prevent oxygen inhibition and improve surface cure without over-exposing underlying layers.

Closing practical notes

Match photoinitiator absorption curves to lamp emission for efficient cure. Favor LED for heat-sensitive, narrow-web label runs when ink formulations permit. Maintain dose measurement and routine maintenance to ensure consistent performance. Troubleshoot methodically: change one variable at a time and document results for continuous improvement.

This technical tutorial provides a practical roadmap for implementing and optimizing UV and LED curing in flexo and offset environments. Apply the process controls and diagnostic steps here to reduce downtime, improve print quality and accelerate finishing operations.