In the fast-paced world of commercial printing, achieving rapid turnaround times without compromising quality is a constant challenge. With the rise of UV LED curing systems, printers now have an innovative way to enhance productivity, especially in sectors like label, flexo, and narrow-width printing. These advanced curing solutions provide a combination of speed, energy efficiency, and superior curing performance, transforming traditional workflows.

The Role of LED UV Curing in Modern Print Production

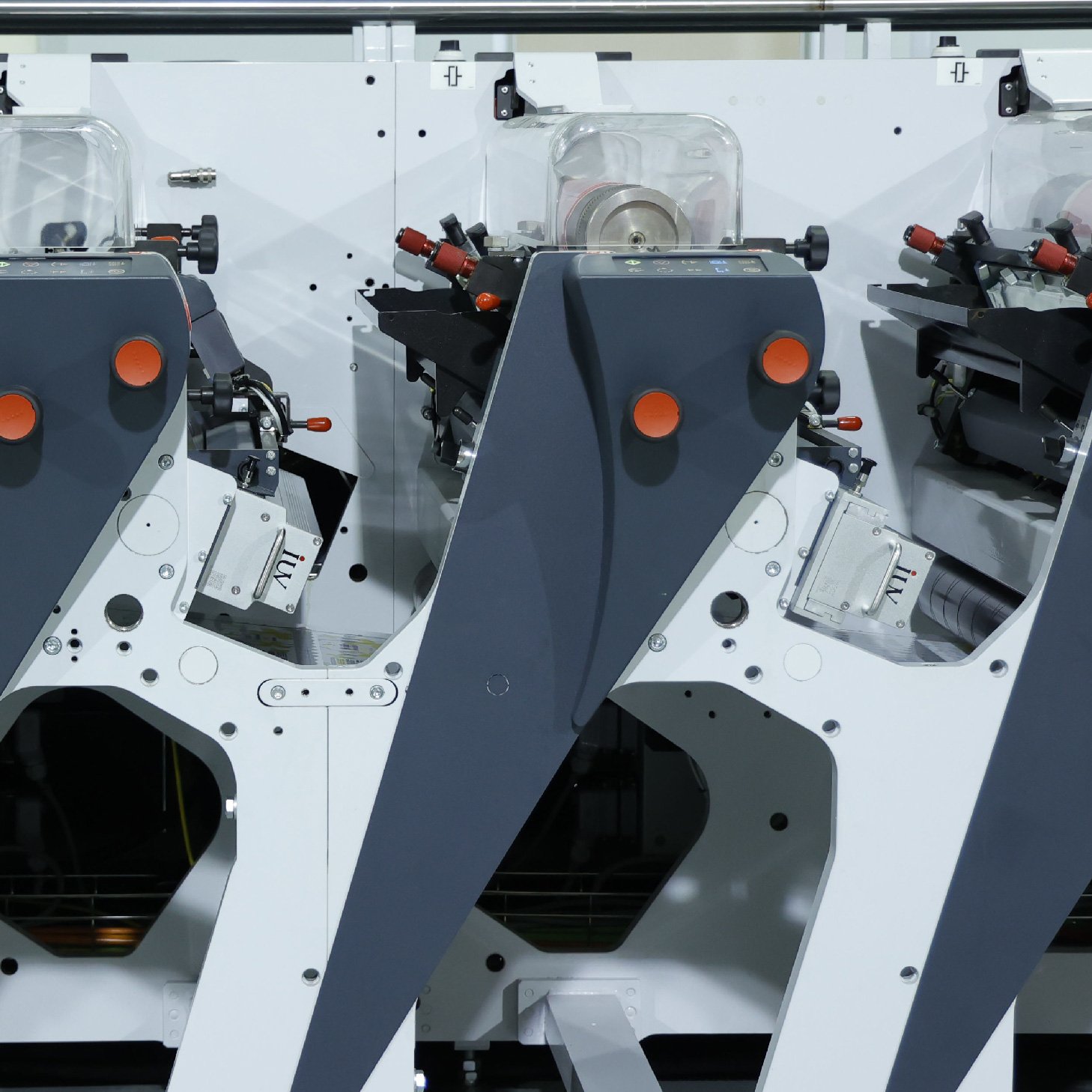

LED UV curing technology stands out for its ability to deliver instant, high-quality curing with minimal heat generation. Unlike conventional UV lamps, LED systems generate a focused wavelength of light that efficiently initiates the photopolymerization process. This not only speeds up production but also reduces energy consumption and extends equipment lifespan. For printers, this translates into faster job turnaround, lower operational costs, and increased flexibility in handling diverse substrates.

Benefits for Label Printing and Flexible Packaging

Label printing demands precision and durability, especially when working with various materials like plastics, foils, and papers. LED UV curing systems ensure that inks and adhesives dry quickly, even on non-porous surfaces, leading to sharper images and vibrant colors. Moreover, fast curing reduces the risk of smudges and delays, allowing for rapid packaging line integration. The targeted wavelength of LED UV also minimizes substrate distortion, maintaining label integrity and adhesive performance.

Optimizing Flexo and Letterpress Processes

Flexographic and letterpress printing often encounter bottlenecks related to curing time. LED UV technology addresses these issues by curing inks immediately after application, enabling faster press speeds and higher throughput. Their instant curing characteristic means fewer interruptions for drying or heat-related issues, resulting in more consistent print quality and fewer waste rejections. Additionally, the reduced heat footprint of LED UV minimizes warping of thin or heat-sensitive materials.

Narrow-Width Printing and the Need for Speed

Narrow-width printing, such as in specialized industrial or decorative applications, benefits significantly from LED UV curing’s rapid response time. These systems can be precisely calibrated for small formats, ensuring uniform curing across tiny substrates. This level of control allows for complex, multi-layered jobs to be completed efficiently, increasing overall equipment uptime. Rapid turnaround in narrow-width applications supports just-in-time manufacturing and quick deliveries.

How LED UV Enhances the Quality of UV Cured Prints

Achieving high-quality prints involves more than speed. LED UV curing systems ensure thorough curing of inks and coatings, which enhances gloss, scratch resistance, and chemical stability. This robustness extends the lifespan of printed labels and packaging, making them suitable for demanding environments like food contact or outdoor exposure. The instant curing also locks in vibrant colors and fine details, providing clients with visually appealing results.

Technical Advantages of LED UV over Conventional UV Systems

Traditional mercury vapor UV lamps require warm-up times and have shorter lifespans. They also produce significant heat that can cause substrate distortion, especially with thin or delicate materials. LED UV systems eliminate these issues with instant start-up and low heat emissions. Their lower power consumption reduces operational costs, providing a greener, more sustainable solution. Maintenance is simplified, as LEDs have longer operational hours and need fewer replacements.

Improving Workflow and Reducing Waste

In high-performance printing environments, minimizing waste is critical. LED UV curing’s consistency and quick curing times reduce the likelihood of smudging, double impressions, and substrate distortion. This means less material waste and fewer reprints. The ability to rapidly switch between jobs and substrates enhances overall workflow efficiency, enabling businesses to meet tight deadlines and manage fluctuating order volumes effectively.

Future Trends in UV Curing Technology

As LED UV technology matures, integration with digital workflows, remote monitoring, and automation will further streamline operations. Smart systems can adjust curing parameters on-the-fly based on substrate and ink characteristics, ensuring optimal results each time. Continued innovation promises even faster curing speeds, broader substrate compatibility, and enhanced environmental benefits, making LED UV a cornerstone of high-speed, high-quality printing.

Selecting the Right LED UV Curing System

Choosing an optimal LED UV system involves considering factors like wattage, wavelength, compatibility with existing equipment, and the types of inks and substrates used. For label and narrow-width printing, systems with precise control and variable power settings deliver the best results. Compatibility with different coatings and adhesives also enhances versatility. Partnering with manufacturers who offer comprehensive support and training can maximize system performance and ROI.

Conclusion

Implementing high-performance LED UV curing technology can revolutionize your printing operation. Its speed, energy efficiency, and superior curing capabilities enable faster turnaround times across various printing techniques such as label, flexo, and narrow-width printing. As a result, businesses gain a competitive edge by delivering high-quality printed materials quickly, sustainably, and reliably. Staying ahead in the dynamic print market requires embracing innovations that meet the demands of efficiency and excellence—LED UV curing stands at the forefront of this evolution.