Hybrid UV and LED Curing Systems: Finding the Right Balance in Narrow Web Printing

In the world of narrow web printing, especially in label, flexographic, and UV printing processes, selecting the right curing system is crucial for achieving optimal results. Hybrid UV and LED curing systems are becoming increasingly popular for their ability to balance speed, quality, and energy efficiency. The right combination of these technologies can greatly improve productivity while maintaining the highest print quality standards. This article explores the key aspects of hybrid curing systems and how to find the ideal balance for various printing applications.

Understanding Hybrid Curing Systems

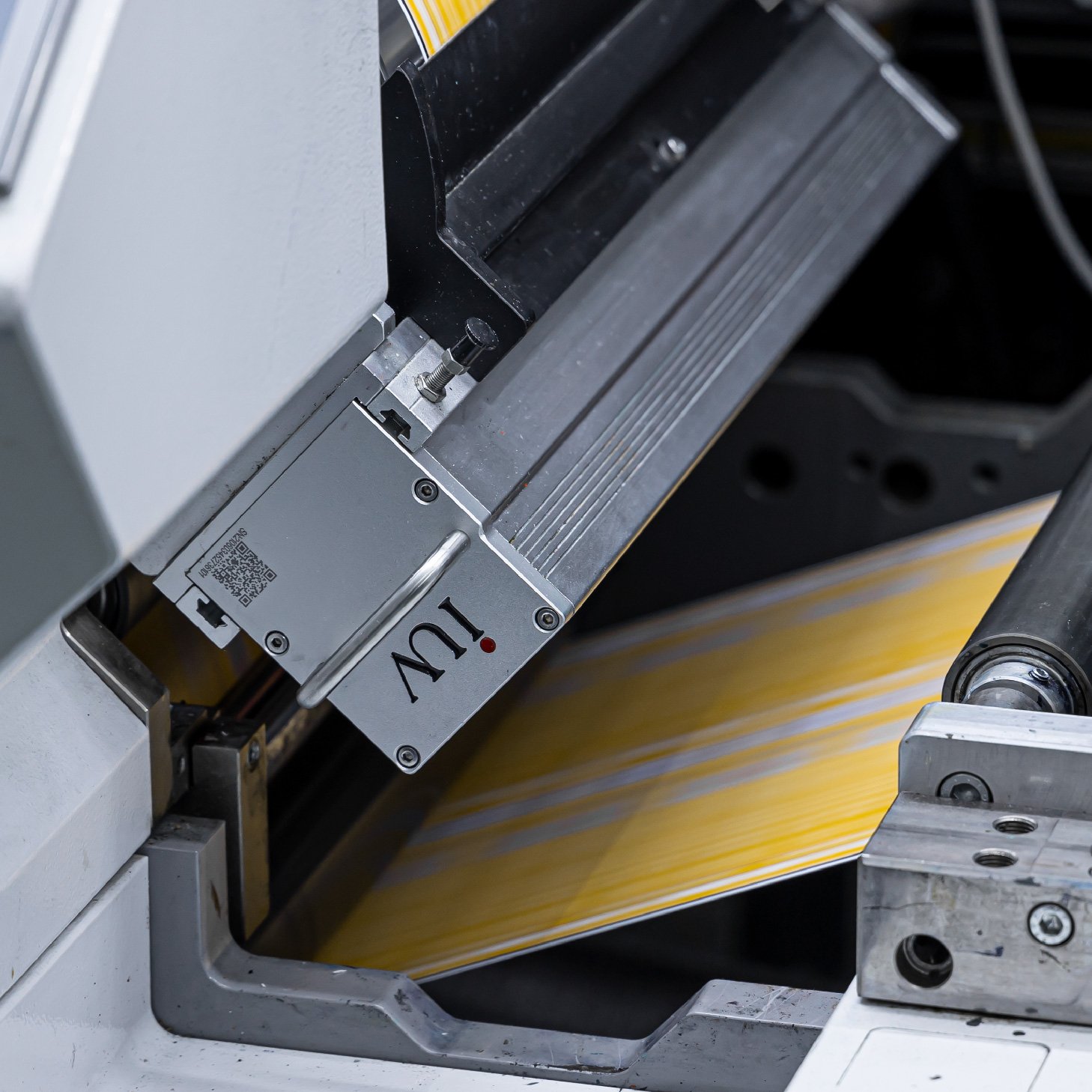

Hybrid curing systems integrate both UV and LED technologies to offer greater flexibility in curing inks on a wide range of substrates. Traditional UV curing uses mercury vapor lamps that emit ultraviolet light, which rapidly cures ink upon contact. However, LED curing systems, which rely on light-emitting diodes, provide a more energy-efficient and environmentally friendly solution, offering instant-on, longer-lasting, and cooler operation.

A hybrid system combines both curing methods in a single machine, allowing printers to choose between the two depending on the specific job requirements. This dual approach allows for greater versatility, enabling printers to cure a wide variety of inks with different curing needs and optimize their production process for different types of substrates.

The Benefits of Hybrid Curing in Narrow Web Printing

- Improved Print Quality

Hybrid UV and LED curing systems enhance print quality by providing superior curing performance. UV curing, known for its fast drying time, ensures crisp, vibrant colors with excellent adhesion to various substrates. LED curing provides consistent, high-intensity light that can cure inks at lower temperatures, reducing the risk of distortion or warping on heat-sensitive materials like films and foils. By combining both technologies, printers can achieve superior results across a broad spectrum of materials.

- Increased Energy Efficiency

One of the main advantages of hybrid curing systems is their energy efficiency. LED curing uses significantly less power than traditional UV curing systems, reducing electricity consumption and lowering operational costs. Additionally, LED systems generate less heat, which can prevent issues such as curling or distortion of delicate materials. This energy-saving capability is not only cost-effective but also environmentally friendly, making it an attractive option for sustainability-conscious businesses.

- Faster Drying Times

Speed is a critical factor in the narrow web printing industry, where production time and turnaround are vital. UV curing provides rapid ink curing, while LED curing systems offer instant-on capability and faster curing times compared to conventional UV lamps. By integrating both technologies, hybrid systems can deliver faster production speeds without compromising on quality, improving overall efficiency and meeting tight deadlines.

- Enhanced Substrate Compatibility

Hybrid systems offer greater flexibility in terms of substrate compatibility. While traditional UV curing may struggle with certain materials, such as heat-sensitive films, LED curing systems provide a cooler curing process, making them suitable for a broader range of substrates. This is particularly important in narrow web applications like label printing, where a variety of substrates, including paper, films, and foils, are often used.

Finding the Right Balance Between UV and LED Curing

When selecting the right hybrid curing system for a specific printing job, it’s important to understand the advantages and limitations of both UV and LED technologies and how they can complement each other. The balance between the two curing methods will depend on several factors, including:

- Ink Type: Different ink formulations have varying curing requirements. UV inks tend to cure more effectively with traditional UV lamps, while LED inks are specifically designed for LED curing systems. A hybrid system offers the flexibility to choose the most appropriate curing method based on the ink type.

- Substrate: The choice of substrate is critical in determining which curing system to use. For example, if you’re printing on heat-sensitive materials, LED curing may be the better choice due to its lower heat generation. On the other hand, thicker materials or those that require higher energy to cure may benefit from UV curing.

- Production Speed: While LED curing systems are fast, UV curing can sometimes deliver even quicker curing times. Hybrid systems allow printers to adjust the curing speed depending on the job’s complexity and speed requirements.

- Cost Considerations: LED systems generally have a higher upfront cost, but they are more energy-efficient and require less maintenance over time. UV curing systems, while less expensive to purchase initially, can have higher energy costs and require regular lamp replacements. Finding a balance between these cost factors is crucial for long-term profitability.

Hybrid Curing for Different Printing Techniques

The versatility of hybrid curing systems makes them suitable for a wide range of narrow web printing techniques, such as label printing, flexographic printing, and gravure printing. Here’s how hybrid systems can be applied to different printing methods:

- Label Printing

In the label printing sector, where substrates vary widely from paper to films, hybrid UV and LED curing systems offer the flexibility to produce high-quality, durable labels with excellent print clarity. The ability to switch between UV and LED curing allows printers to handle both rigid and flexible substrates without compromising on curing quality. - Flexographic Printing

Flexographic printing, often used for packaging and label applications, benefits from hybrid curing systems by allowing printers to achieve high-quality results on different substrates. The ability to use LED curing for heat-sensitive materials and UV curing for more robust substrates ensures that each job is completed to the highest standards, regardless of the material type. - Narrow Web Printing

In narrow web printing, which is often used for labels, packaging, and security printing, hybrid curing systems help optimize production speeds and print quality. Whether printing on paper, plastic films, or other substrates, the hybrid system ensures efficient curing, delivering prints with excellent adhesion and durability.

Conclusion

Hybrid UV and LED curing systems offer a powerful solution for the narrow web printing industry, providing the flexibility to handle a wide range of substrates, inks, and production requirements. By finding the right balance between the two technologies, printers can achieve optimal curing performance, improved energy efficiency, and faster drying times while maintaining high-quality prints. With advances in curing technology continuing to shape the future of the printing industry, hybrid systems represent a forward-thinking solution that balances both quality and sustainability.