The Hidden Advantages of LED Curing Systems for Narrow Web Printers

In the fast-evolving world of narrow web printing, operators are constantly seeking methods to improve productivity, reduce costs, and enhance print quality. Among the most significant advancements is the adoption of LED curing systems, particularly in applications such as label printing, flexo, letterpress, and plate printing. These systems offer a range of benefits that can transform how printers operate, providing both direct and indirect advantages that often go unnoticed.

Understanding LED Curing Technology in Narrow Web Printing

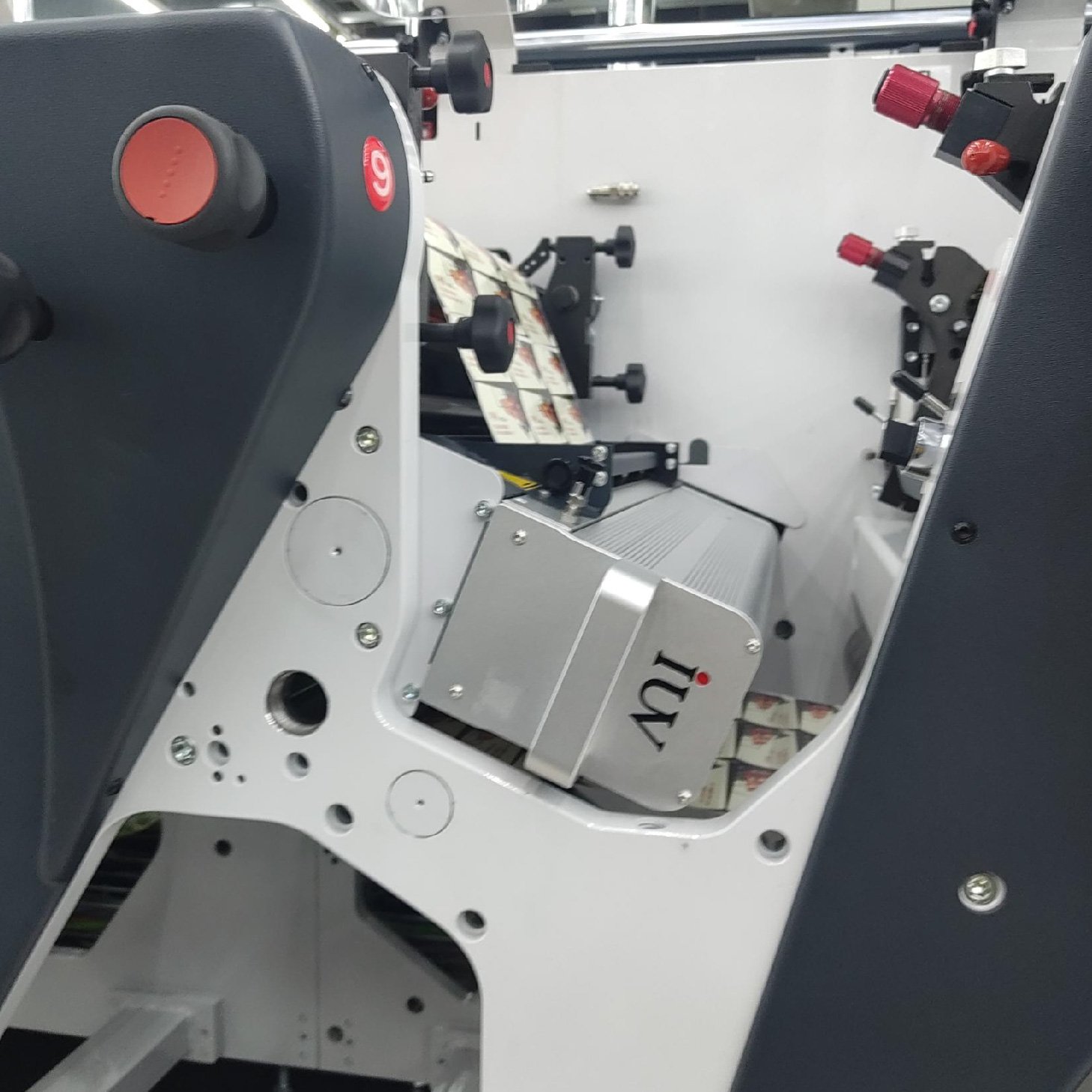

LED curing technology involves the use of LED lights to instantly cure UV inks, coatings, and adhesives. Unlike traditional mercury vapor lamps, LEDs generate UV light with specific wavelengths, which results in faster curing times, lower energy consumption, and less heat generation. This technology is especially suited for narrow web printers where precision and speed are paramount.

When integrated with label, flexo, or plate printing processes, LED UV systems facilitate a seamless workflow capable of meeting the high demands of small-run, custom, or complex print jobs. Their compact design allows easy installation within existing press configurations, making them an attractive choice for printers seeking modernization without major overhauls.

Enhanced Efficiency and Throughput

One of the most appreciated benefits of LED curing systems is their ability to significantly boost production speed. Traditional UV lamps often require warm-up times and lengthy curing durations, leading to bottlenecks in high-volume settings. In contrast, LED systems cure instantly the moment the UV light contacts the ink, allowing continuous printing without delays.

This increase in throughput translates directly into higher daily output and quicker turnaround times, vital for label and flexible packaging markets. The rapid curing also minimizes ink transfer issues, creating crisp, vibrant images with sharp detail — especially critical in narrow web applications where precision is key.

Cost Savings and Energy Efficiency

Switching to LED UV curing yields notable cost advantages over traditional lamp systems. LEDs consume substantially less power, often cutting energy costs in half. They also have longer operational lifespans — often exceeding 20,000 hours — which reduces maintenance and replacement expenses.

Furthermore, their instant-on capability eliminates the need for warm-up periods, meaning printers can start jobs immediately. Reduced heat output not only saves energy but also minimizes wear on sensitive materials, enabling a broader range of substrates such as thin films, specialty papers, and label stocks.

Superior Print Quality and Consistency

LED curing systems contribute to exceptional print clarity, gloss, and color vibrancy. Because curing is instantaneous and uniform, inks and coatings dry evenly, reducing smudging, blocking, and set-off issues. This is especially advantageous in label printing, where vibrant, high-resolution images impact product appeal and brand recognition.

In flexo and plate-based printing, consistent curing minimizes streaks and uneven adhesion, ensuring every print meets strict quality standards. Additionally, LED UV inks are formulated to produce less volatile organic compounds (VOCs), leading to safer work environments and environmentally friendly processes.

Expanded Substrate Compatibility

Flexibility in substrate selection is critical for narrow web printers handling diverse jobs. Traditional UV curing systems may struggle with heat-sensitive materials, limiting options. LED UV systems emit little to no heat, making them ideal for delicate substrates like thin films, PET, and specialty label materials.

This expanded compatibility enables printers to explore new markets and applications, including security labels, promotional stickers, and flexible packaging. The ability to cure on sensitive materials without warping or deformation opens avenues for innovative product designs and finishes.

Environmental and Regulatory Advantages

Regulatory pressures and sustainability goals are influencing the printing industry profoundly. LEDs’ low energy consumption and absence of mercury align with eco-conscious initiatives. Their instant curing reduces volatile emissions, contributing to cleaner production environments.

Additionally, LED systems typically require less cooling and minimal waste disposal, further reducing the environmental footprint. These factors appeal to clients seeking eco-friendly packaging solutions while helping printers meet evolving regulatory standards without sacrificing efficiency.

Simplified Maintenance and Reduced Downtime

Maintenance teams benefit from the robustness of LED systems. Because LEDs are solid-state devices with no moving parts or fragile filaments, they are less prone to failure. This reliability translates into reduced downtime, ensuring continuous operations and meeting tight deadlines.

Moreover, LED UV systems generate less heat and require no warm-up periods, decreasing the likelihood of equipment overheating or burnouts. The result is a more stable workflow, fewer interruptions, and lower repair costs, all contributing to a more predictable production schedule.

Practical Considerations for Implementation

While LED curing offers numerous advantages, successful integration requires careful planning. Practitioners should assess their current press configurations, substrates, and ink formulations. Compatibility with existing inks and coatings must be confirmed, and adjustments to curing settings may be necessary to optimize performance.

Investing in training for operators ensures the full benefits of LED systems are realized. From maintenance routines to troubleshooting, understanding the intricacies of LED UV curing enhances equipment longevity and print quality.

Future Trends and Innovations

Looking ahead, advancements in LED UV technology are poised to further revolutionize narrow web printing. Increased wavelength control, higher power outputs, and smarter integration with press automation will enable even faster curing and better energy efficiency.

Additionally, the development of dedicated LED UV inks tailored to specific applications will expand possibilities for highly specialized label and flexible packaging products. As the technology matures, expect to see LED curing systems become standard in the industry, unlocking new levels of quality, speed, and sustainability.

The adoption of LED curing systems in narrow web printing unlocks a range of hidden advantages that extend beyond quick curing times. From cost savings and enhanced quality to substrate versatility and environmental benefits, these systems are shaping the future of label, flexo, and plate printing. Embracing this technology can position printers ahead of the competition, ready to meet the demands of an ever-evolving marketplace.