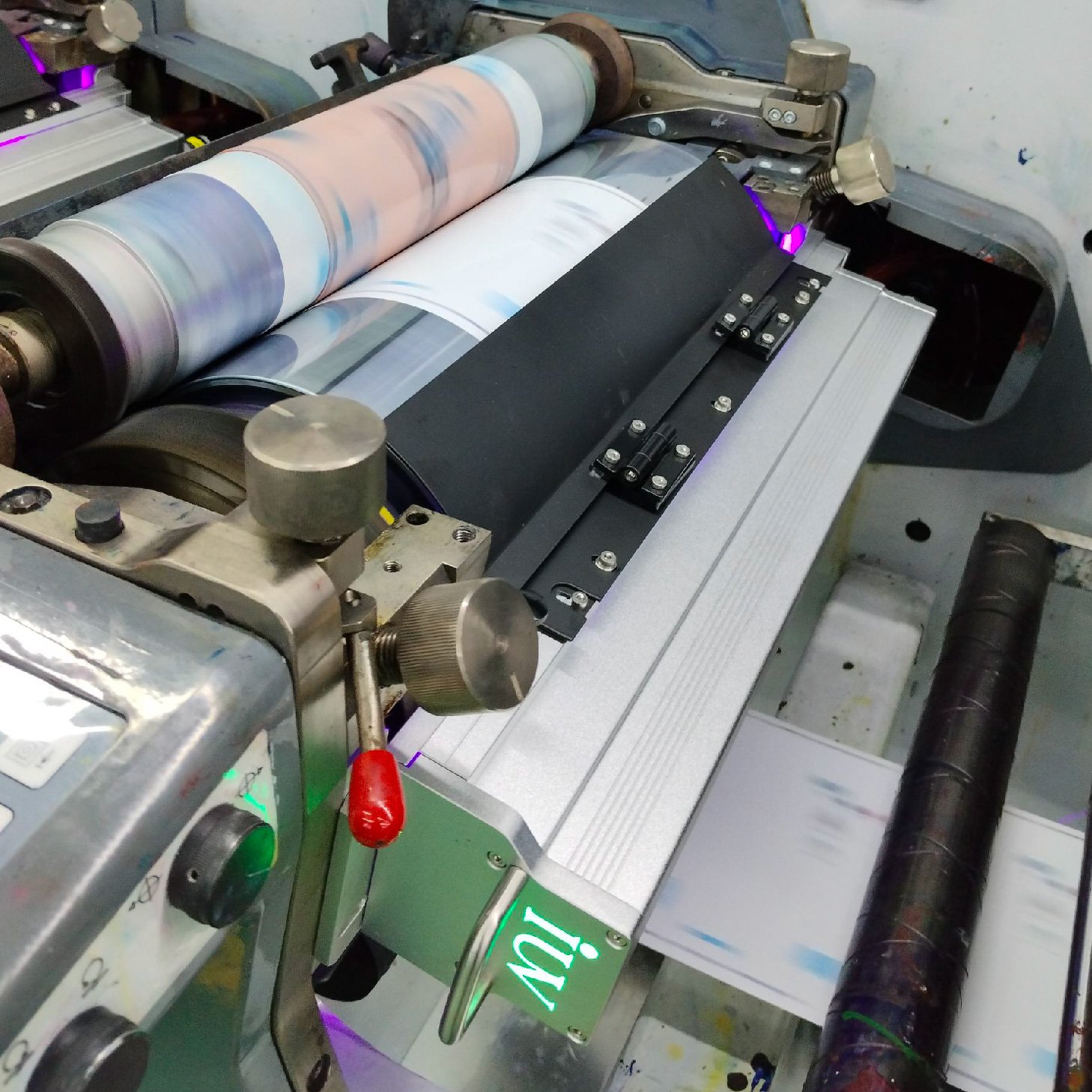

LED UV curing technology has revolutionized the printing industry. It offers faster drying times, lower energy consumption, and reduced heat output compared to traditional mercury lamps. This makes it ideal for label printing, flexographic printing, offset printing, and narrow web applications. However, like any advanced technology, LED curing systems can encounter issues. Addressing these problems promptly ensures optimal print quality and minimizes downtime.

One prevalent challenge is uneven curing. This often manifests as tacky ink surfaces or areas where ink hasn’t fully hardened. A primary cause is inconsistent light intensity across the LED array. Check for blocked or dirty LED heads. Even a small amount of ink mist or dust can significantly impede light output. Regular cleaning of the LED modules is vital. Ensure the distance between the LED array and the substrate remains constant. Variations in this gap can lead to intensity differences. Also, verify that the power supply to each LED module is stable. Fluctuations can cause uneven performance.

Another common problem is delamination or poor adhesion. This occurs when the UV ink doesn’t bond properly with the substrate. Insufficient UV dosage is a frequent culprit. This means the LEDs aren’t providing enough energy for the ink to cure fully. Check your UV dosage settings. Ensure they align with the ink manufacturer’s recommendations for the specific substrate being used. The speed of the printing press also plays a critical role. A faster press speed requires a higher UV intensity from the LEDs to achieve adequate curing. If the press speed has been increased, the LED power may need to be adjusted accordingly.

Substrate compatibility is also key. Some substrates, especially those with high levels of additives or certain surface treatments, can absorb or reflect UV light differently. This can hinder proper curing. Always test new substrates with your specific LED curing system and UV ink formulation. Contamination on the substrate surface can also interfere with adhesion. Ensure your printing environment is clean. Any oils or release agents can prevent the ink from bonding.

Ink formulation is another critical factor for successful LED curing. Not all UV inks are designed for LED curing. Ensure you are using inks specifically formulated for LED UV lamps. These inks have photoinitiators that are highly sensitive to the specific wavelengths emitted by LED lamps (typically 365nm, 385nm, 395nm, or 405nm). Using an ink designed for mercury lamps will likely result in poor or incomplete curing with an LED system. Consult with your ink supplier to confirm compatibility.

Overheating of the LED system itself can lead to reduced performance and premature failure. LED modules generate heat, and while they produce less than mercury lamps, proper cooling is still essential. Ensure the ventilation systems for your LED curing unit are clear and functioning correctly. Dust and debris can accumulate in cooling fans and heat sinks, reducing their efficiency. Monitor the operating temperature of the LED modules. If they are consistently running too hot, it could indicate a problem with the cooling system or an overloaded power supply.

Sometimes, issues arise from the interaction between the LED system and the printing press. For narrow web flexographic presses, the integration of the LED curing unit needs careful consideration. Ensure the unit is securely mounted and properly aligned with the print stations. Misalignment can lead to uneven exposure and inconsistent curing across the width of the label. The speed synchronization between the press and the curing unit is also crucial. If the LED system isn’t keeping pace with the press speed, under-curing will occur.

For offset printing applications, particularly in sheet-fed or web offset, the thicker ink layers often used can pose a challenge for LED curing. Ensure your LED system has sufficient power and the correct wavelength output to penetrate and cure these thicker ink films. Multiple LED curing units might be necessary for some offset applications.

In tag printing, where often small details and vibrant colors are paramount, incomplete curing can result in smudging and poor color density. Troubleshoot by ensuring the LED wavelength is optimal for the specific pigments in your inks. High-opacity white inks, for instance, can sometimes block UV light from reaching lower ink layers. This might require specific LED configurations or ink adjustments.

When troubleshooting, it’s helpful to isolate the problem. If you’re experiencing consistent issues, try running a test print with a known good ink and substrate combination at a slower press speed with increased LED power. This can help determine if the problem lies with the ink, substrate, press speed, or the LED system itself. Keep detailed logs of your settings, any changes you make, and the results you observe. This systematic approach can quickly pinpoint the source of the malfunction.

Regular maintenance is the best defense against most common issues. This includes cleaning LED heads, checking power connections, ensuring cooling systems are free of obstructions, and verifying that the UV output is within specifications. Many modern LED curing systems come with diagnostic software that can alert you to potential problems before they become critical. Utilizing these features can save significant time and resources in the long run. By understanding these potential pitfalls and employing a systematic troubleshooting approach, printers can maximize the benefits of their LED UV curing systems.