Bright, vibrant labels are often the first thing that catches a customer’s eye. In the competitive world of narrow web printing, achieving superior color density and a high-gloss finish isn’t just about aesthetics; it’s about brand impact and product appeal. The technology behind achieving these visual benchmarks has seen significant advancements, with LED UV curing systems emerging as a transformative force.

Traditional UV curing methods have long been a staple in the printing industry. However, they often come with drawbacks. High heat output, shorter lamp lifespans, and inconsistent energy delivery could lead to variations in print quality. This is where the precision and efficiency of LED UV curing systems truly shine, especially when it comes to enhancing color density and achieving that coveted gloss.

Color density is directly related to how well ink is applied and how effectively it’s cured. With LED curing, the light emitted is highly focused and at specific wavelengths. This allows for a more precise and efficient transfer of energy to the UV-reactive inks. The result is ink that cures rapidly and uniformly across the entire printed surface. This thorough curing process ensures that the pigments within the ink maintain their integrity and opacity, leading to richer, deeper colors that pop off the substrate. Unlike older methods that might “bake” the ink unevenly, LED systems deliver a consistent “hit” of curing energy, preventing premature drying or incomplete polymerization.

This enhanced color density is particularly crucial in label printing. Whether it’s a vibrant food label, a sophisticated cosmetic package, or a durable industrial product label, the colors need to be accurate and impactful. Flexographic printing, a common method for narrow web labels, benefits immensely from this. The precise control offered by LED curing ensures that the fine details and gradients in the artwork are rendered with exceptional fidelity. The inks are cured almost instantly, preventing them from spreading or losing their sharpness, which is vital for maintaining crisp text and intricate graphics.

The gloss factor is another area where LED curing systems excel. A high-gloss finish not only makes a label look premium but also offers practical benefits, such as improved scuff resistance and easier cleaning. LED curing achieves this gloss through several mechanisms. Firstly, the rapid and complete curing of the ink surface creates a smoother, more consolidated layer. This smoothness reflects light more uniformly, resulting in a brilliant, high-gloss appearance. Secondly, the lower heat output of LED lamps means the ink is less likely to degrade or yellow during the curing process, preserving the original vibrancy and sheen.

In offset printing, also known as lithographic printing, consistent gloss is equally important, especially for high-end packaging and commercial applications. LED curing ensures that the ink layers, whether thin or thick, are cured efficiently and evenly. This even curing prevents the formation of micro-imperfections on the ink surface that can scatter light and diminish gloss. The result is a mirror-like finish that adds a touch of luxury and perceived value to the printed product.

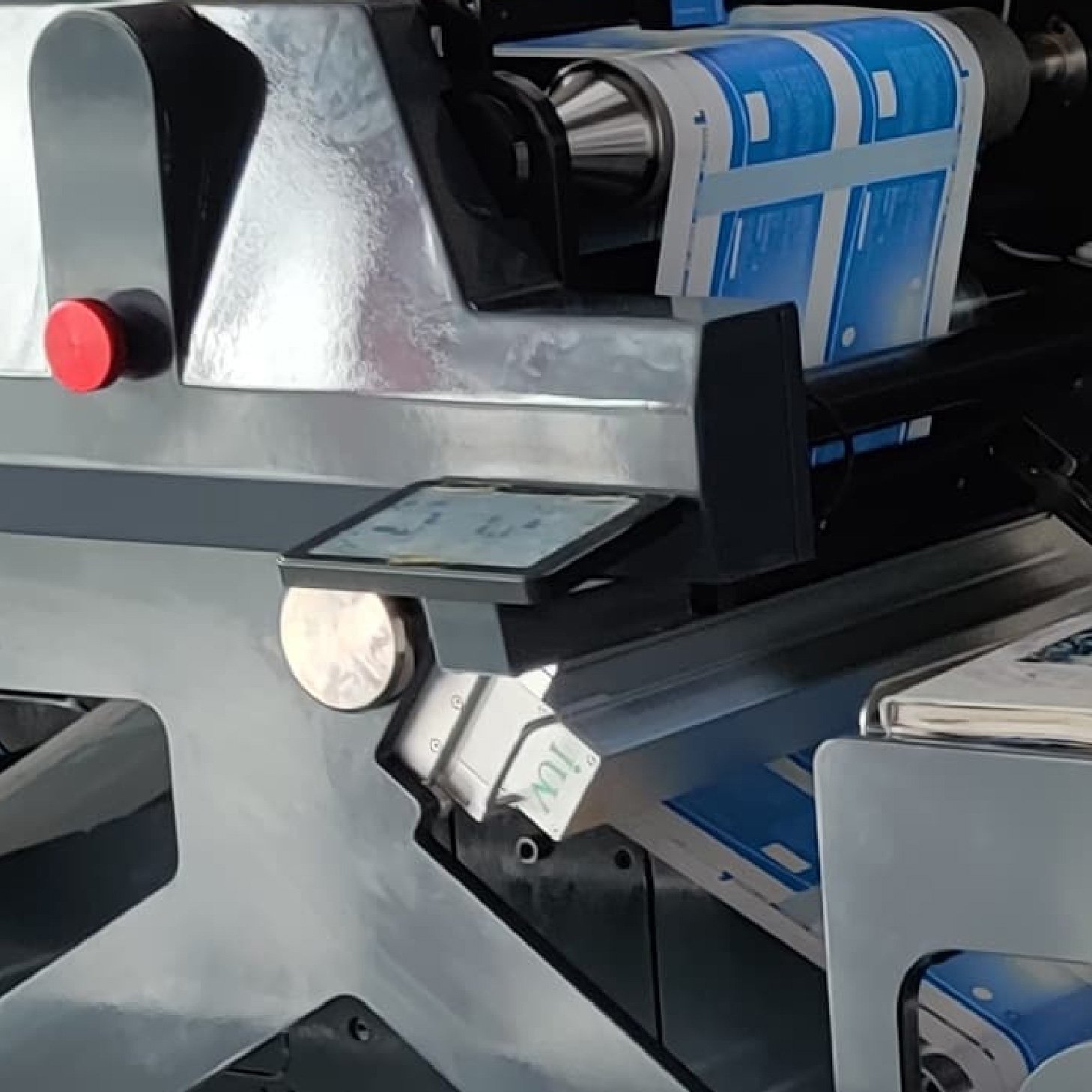

The narrow web printing sector, encompassing labels and flexible packaging, has been a primary adopter of LED UV curing technology. The compact nature of LED systems makes them ideal for fitting into existing narrow web presses without major modifications. This ease of integration, combined with their operational efficiencies, makes them an attractive upgrade. Printers can achieve faster line speeds because LED curing is so instantaneous, leading to increased productivity. This speed doesn’t come at the expense of quality; in fact, it often improves it, as inks are cured before they have a chance to experience detrimental environmental factors.

The environmental benefits of LED curing also contribute to its appeal. LED lamps consume significantly less energy compared to traditional mercury vapor lamps. They also do not contain mercury, making disposal more environmentally friendly. Furthermore, the lower heat output means less strain on cooling systems and a generally more comfortable working environment. This energy efficiency translates into lower operating costs for print businesses, a significant advantage in a cost-sensitive industry.

The spectral output of LED lamps can be precisely controlled. This means that printers can choose specific wavelength LEDs that perfectly match the spectral requirements of their UV inks. This tailored approach to curing ensures optimal ink polymerization, leading to enhanced physical properties of the cured ink film, including improved adhesion, scratch resistance, and chemical resistance, all while boosting color density and gloss.

For flexographic printers, this precision means achieving repeatable results job after job. The consistency in color and finish is paramount for brand owners who rely on their packaging to maintain a uniform brand image across all products and regions. The ability of LED curing to deliver this consistency, even on challenging substrates, is a major advantage. The rapid cure also allows for immediate post-processing, such as die-cutting or rewinding, without the risk of smudging or marring the freshly printed ink.

In the realm of offset printing for labels, the transition to LED curing offers a pathway to cleaner, more efficient production. The absence of ozone production, common with older UV technologies, improves air quality in the print shop. The faster turnaround times enabled by LED curing can help businesses meet tighter deadlines and respond more quickly to market demands. This agility, coupled with the superior color density and gloss achieved, positions print providers using LED technology as industry leaders.

The interplay between ink formulation and LED curing technology is also advancing rapidly. Ink manufacturers are developing new UV-curable inks specifically designed to leverage the precise wavelengths and energy profiles of LED systems. These advancements further optimize the curing process, allowing for even greater vibrancy, deeper color saturation, and more brilliant gloss finishes than ever before.

Ultimately, the adoption of LED UV curing systems represents a significant leap forward for the printing industry, particularly for narrow web, flexographic, and offset applications focused on labels. The enhanced color density translates to more impactful branding and visually appealing products. The superior gloss finish elevates the perceived quality and premium feel of the printed material. Combined with the operational efficiencies, environmental benefits, and improved consistency, LED curing technology is not just a trend; it’s a fundamental enhancement to the art and science of modern printing, ensuring labels and packaging captivate and endure.