The label printing industry is always seeking innovation. Enhancements that boost efficiency and product quality are highly valued. One such advancement is the integration of LED curing systems. This technology brings significant advantages to various printing methods, especially for narrow web label printing.

Traditional UV curing systems have been a staple for years. However, LED UV curing represents a leap forward. It’s a technology that is rapidly transforming how labels are produced. For businesses focused on narrow web printing, understanding these advantages is key to staying competitive.

Energy Efficiency is a Major Draw

One of the most compelling benefits of LED curing is its remarkable energy efficiency. Unlike conventional mercury vapor lamps, LEDs consume significantly less power. This translates directly into lower operating costs for printing businesses. The energy savings are substantial over the lifespan of the equipment. Furthermore, LEDs reach their full curing power almost instantly. There is no warm-up time required, unlike older lamp technologies. This speed improves workflow and reduces energy waste.

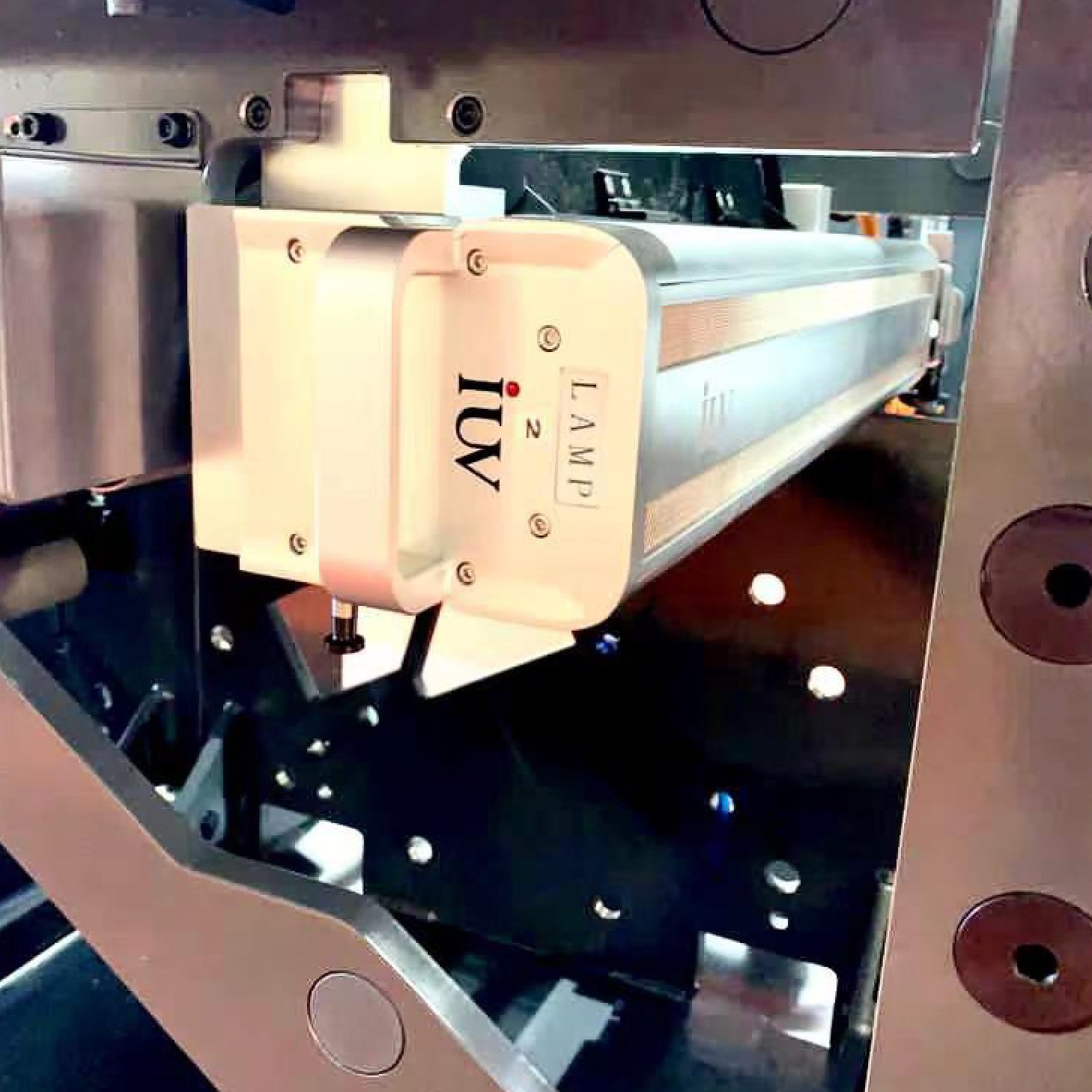

Extended Lamp Life and Reduced Maintenance

The lifespan of LED lamps is another critical advantage. They can last much longer than traditional UV lamps. This means less frequent replacement and reduced downtime for maintenance. Printing operations can maintain consistent production schedules without the interruption of lamp changes. The consistent output from LED lamps also contributes to predictable curing results. This reliability is invaluable in a production environment.

Lower Heat Emission for Sensitive Substrates

LED curing systems emit very little heat compared to mercury lamps. This is a significant benefit when printing on heat-sensitive substrates. Materials like thin films or certain plastics can deform or degrade under high heat. LED technology allows for efficient curing without damaging these delicate materials. This opens up new possibilities for product applications and material choices in label design.

Environmental Benefits of LED Curing

Beyond energy savings, LED curing offers other environmental advantages. Mercury lamps contain hazardous materials. Their disposal requires special handling. LED lamps are free from mercury, making them a more environmentally friendly option. This aligns with a growing global emphasis on sustainable manufacturing practices. Printing companies can showcase their commitment to green initiatives by adopting this technology.

Instant On/Off Capabilities Enhance Productivity

The instant on/off capability of LED curing is a productivity booster. Printing presses can be stopped and started without concern for lamp warm-up or cool-down periods. This flexibility is particularly useful in short-run or variable data printing applications. It minimizes wasted energy and time between jobs. The precise control over curing is also a major plus for achieving high-quality results.

Improved Curing Performance and Ink Compatibility

LED UV curing systems offer excellent curing performance. They provide a focused spectrum of UV light. This targeted wavelength ensures efficient and thorough curing of UV-curable inks and coatings. This results in durable, high-quality labels with excellent adhesion and scratch resistance. Many modern UV inks are specifically formulated for LED curing. This ensures optimal performance and vibrant print results.

Narrow Web Printing and Flexography

For the narrow web printing sector, which often employs flexography, LED curing is a game-changer. Flexographic printing relies on high speeds and consistent ink transfer. LED curing systems are well-suited to these demands. They provide the rapid and efficient curing needed to keep pace with fast press speeds. This is crucial for maintaining print quality and avoiding ink smudging or running.

In flexo, precise ink drying is essential for sharp images and legible text. LED UV units can be precisely controlled to deliver the right amount of UV energy. This ensures that inks cure properly without over-exposure. This consistency is a hallmark of high-quality label production.

Offset and Digital Label Printing

The advantages extend beyond flexography. In offset printing for labels, LED curing can improve throughput and reduce waste. The fast curing means fewer issues with ink transfer to the blanket or subsequent sheets. For digital label printing, especially UV inkjet, LED curing is standard. It enables immediate drying of ink droplets, allowing for complex multi-layer prints and immediate finishing.

Safety and Operational Improvements

LED curing systems are generally safer to operate than traditional UV systems. They produce less ozone, a byproduct of mercury lamps that requires ventilation. The cooler operation also reduces the risk of burns. The robust design of LED lamps means fewer delicate components that can break. This contributes to a safer working environment for press operators.

Cost-Effectiveness in the Long Run

While the initial investment in an LED curing system might be higher, the long-term cost-effectiveness is undeniable. The savings in energy, reduced maintenance, and extended lamp life all contribute to a lower total cost of ownership. For label printers looking to optimize their operations, the return on investment from switching to LED curing is compelling.

Future-Proofing Your Printing Operations

The trend towards LED technology is clear across many industries. Adopting LED curing now positions label printing businesses for the future. As more ink and coating manufacturers develop products optimized for LED, staying current becomes easier. It ensures compatibility with the latest consumables and printing techniques.

In conclusion, integrating LED curing into label printing offers a powerful combination of benefits. From significant energy savings and reduced operational costs to improved print quality and environmental advantages, the case for LED is strong. For narrow web, flexographic, offset, and digital label printers, this technology represents a smart investment in efficiency and excellence.