Flexographic printing, especially in the narrow web sector, is constantly seeking ways to boost efficiency. High-speed presses and demanding turnaround times require robust solutions. One of the most impactful advancements in recent years is the integration of LED UV curing systems. These systems offer a compelling alternative to traditional mercury lamp curing, bringing significant productivity gains to label and flexible packaging printers.

The core of this productivity boost lies in the inherent advantages of LED technology. Unlike mercury lamps that emit a broad spectrum of light, LEDs produce a highly focused wavelength, typically in the UVA range. This precise energy delivery means faster and more complete curing of UV inks and coatings. For a flexo printer, this translates directly into quicker production cycles. Imagine a press running at full speed, with every label or package perfectly cured as it exits the machine. There’s no waiting, no bottlenecks. This seamless process is a major contributor to increased output.

Consider the energy efficiency. LED curing systems consume considerably less power than their mercury lamp counterparts. This reduction in energy usage translates into lower operating costs, a significant factor for any print business looking to improve its bottom line. Furthermore, LEDs generate less heat. This is a crucial point in narrow web printing where heat can warp thinner substrates, leading to print defects and material waste. Cooler running temperatures mean more stable print runs and less downtime due to equipment adjustments or material rejection.

The longevity of LED lamps is another key productivity driver. Mercury lamps have a limited lifespan and require frequent replacement, often involving specialized disposal. LED lamps, on the other hand, can last tens of thousands of hours. This drastically reduces maintenance costs and the frequency of line stoppages for lamp changes. A printer can rely on consistent performance over extended periods, minimizing unforeseen disruptions that eat into valuable production time.

Beyond the direct benefits of speed and reduced downtime, LED curing also enables greater substrate versatility. Because LEDs emit less heat, printers can confidently run a wider array of heat-sensitive materials. This includes delicate films, certain plastics, and even some paper stocks that would be compromised by the heat of traditional curing methods. This expanded capability opens up new market opportunities and allows printers to cater to a broader client base without investing in additional specialized equipment.

The immediate on/off nature of LEDs is also a game-changer. Mercury lamps require a warm-up period to reach full intensity and take time to cool down. LEDs, however, are ready to cure instantly and switch off the moment the print run stops. This instant response minimizes wasted energy and ink during setup and job changes. When switching between different jobs, the rapid on/off functionality means less ink waste and quicker transitions, further enhancing overall throughput.

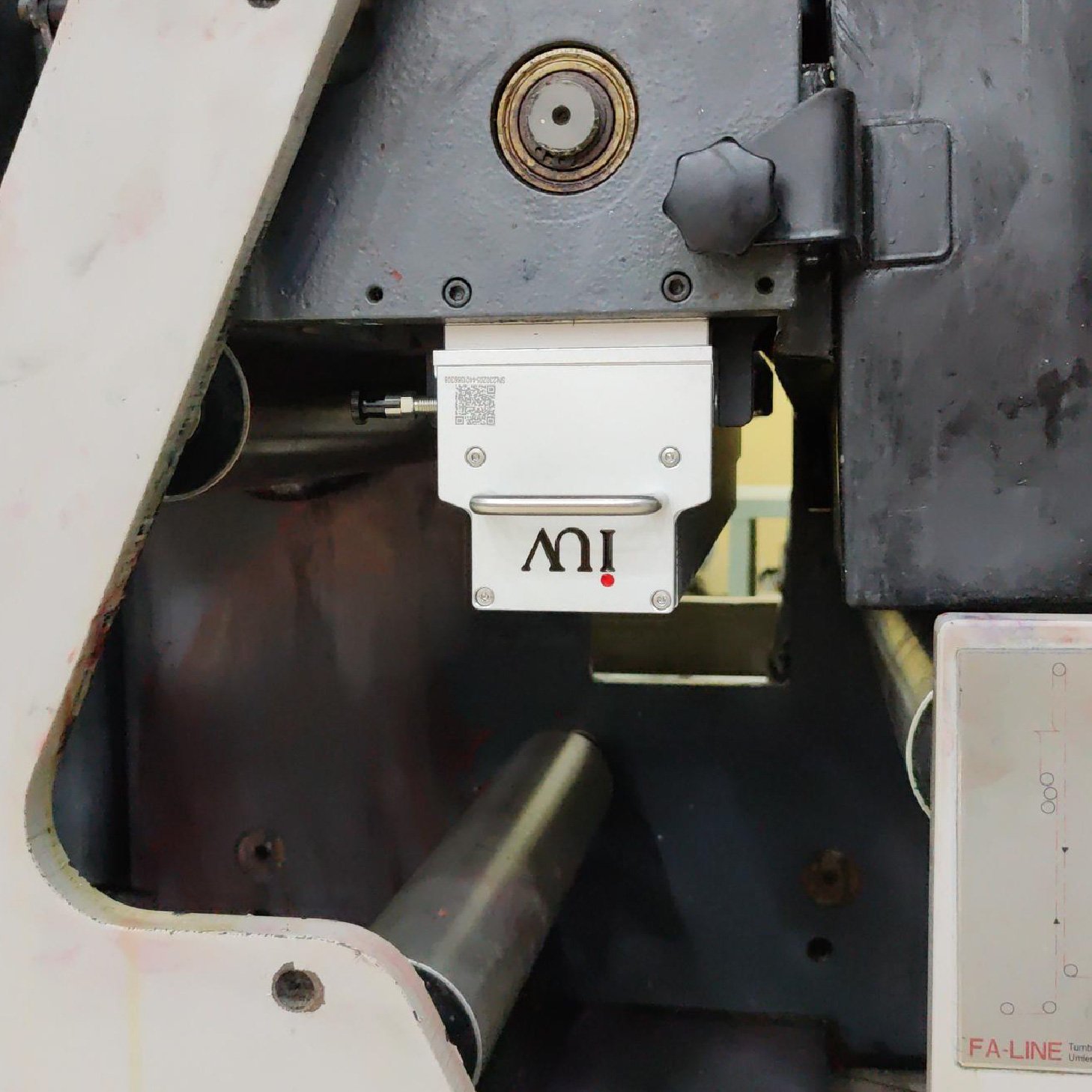

In the realm of narrow web printing, where space is often at a premium, the compact nature of LED curing units is also an advantage. They can be easily integrated into existing press lines or designed into new press configurations without requiring significant modifications. Their smaller footprint and lower heat output contribute to a more comfortable and safer working environment for press operators.

The enhanced curing performance of LEDs also leads to improved print quality. Because the curing is more efficient and targeted, inks and coatings achieve their full physical and chemical properties. This results in better rub resistance, chemical resistance, and overall durability of the printed product. For label printers, this means fewer complaints about print defects and a higher rate of first-pass quality, again contributing to overall productivity by reducing costly rework.

When looking at the total cost of ownership, while the initial investment in LED curing systems might be higher than traditional systems, the long-term savings are substantial. Reduced energy consumption, lower maintenance costs due to longer lamp life, less waste from substrate limitations, and decreased downtime all contribute to a much more favorable economic equation over the lifespan of the equipment. For businesses focused on optimizing flexographic operations, especially in the competitive narrow web market, the transition to LED curing is becoming increasingly a necessity rather than an option.

The technology is also evolving rapidly. Newer LED systems offer even greater energy efficiency and more uniform light distribution across the web. Advancements in LED driver electronics and cooling systems are further enhancing reliability and performance. This continuous innovation ensures that LED curing remains at the forefront of printing technology, providing a clear path for flexographic printers to achieve higher productivity, better quality, and improved profitability.

For label printers and flexible packaging converters, embracing LED UV curing is a strategic move. It’s about leveraging advanced technology to overcome the inherent challenges of high-speed printing. It’s about unlocking new levels of efficiency, reducing operational costs, and expanding the capabilities of their flexographic presses. The impact on productivity is undeniable, making it a critical consideration for any printer aiming to stay competitive in today’s fast-paced market.