Keeping your flexo printing operation running smoothly means caring for your equipment. LED curing units are vital for high-quality output. Proper maintenance ensures they last longer. It also prevents costly downtime. This guide offers practical tips for the care of your LED UV curing systems. We’ll focus on narrow web printing applications.

Flexographic printing, often called flexo, relies on flexible printing plates. These plates transfer ink to a substrate. Narrow web presses are common for labels and flexible packaging. UV LED curing is a key technology in this field. It offers fast drying times and excellent ink adhesion. It’s also more energy-efficient than traditional mercury lamps. But like any industrial equipment, LED units need attention.

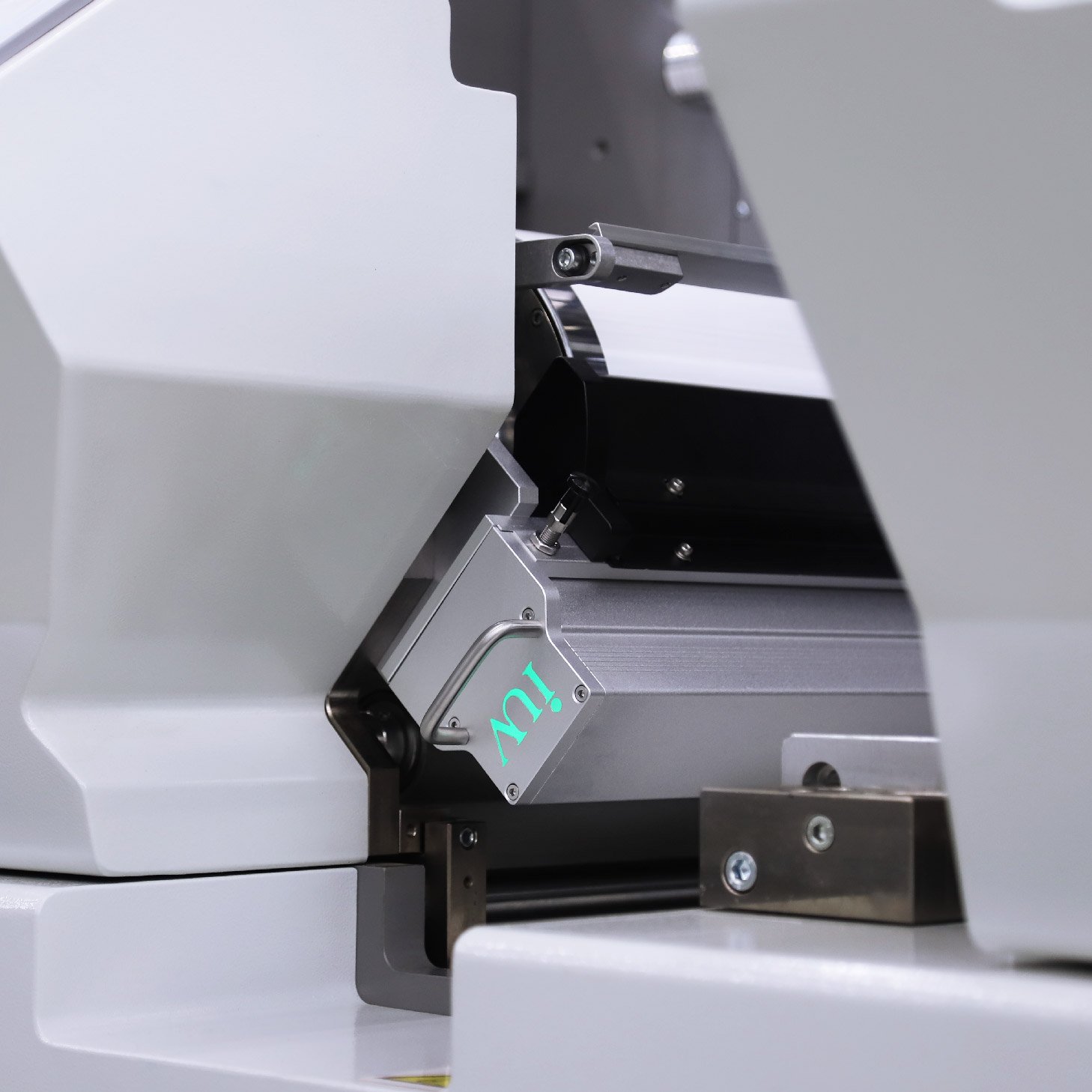

Understanding Your LED Curing Unit

Before diving into maintenance, know your unit. LED curing systems use light-emitting diodes. These diodes emit UV light at specific wavelengths. This light initiates the polymerization of UV-curable inks and coatings. Different LEDs emit light in different parts of the UV spectrum. Knowing the specific wavelengths your unit uses is helpful. This detail impacts ink and coating selection. It also affects how you troubleshoot.

Daily Checks: A Foundation for Longevity

- Visual Inspection: Start each day with a quick look. Check for any visible damage to the LED heads or housing. Look for dust or debris accumulation. Any foreign material can block light output or cause overheating.

- Cooling System: Most LED units have active cooling. This can be air or water-based. Ensure fans are running freely. Check for obstructions in air intakes. If you have a water-cooled system, monitor coolant levels and flow. Leaks or blockages are serious issues.

- Power and Connections: Verify all power cables and connections are secure. Loose connections can lead to intermittent power or electrical faults. Ensure no cables are frayed or damaged.

Weekly Maintenance: Deeper Cleaning and Monitoring

- Lens Cleaning: The lenses over the LED emitters are critical. They direct the UV light onto the substrate. Dust, ink spray, or dried coatings can build up here. Use a soft, lint-free cloth. A mild, approved cleaning solution might be necessary. Always follow the manufacturer’s recommendations for cleaning agents. Never use abrasive materials. Scratched lenses reduce curing efficiency.

- Filter Check: Air filters on cooling systems need regular attention. Dust-clogged filters restrict airflow. This leads to higher operating temperatures. Higher temperatures shorten the lifespan of the LEDs. Clean or replace filters as needed. This is a simple but effective step.

- Interlock Switches: Ensure all safety interlock switches are functioning correctly. These prevent the unit from operating if guards are not in place. Safety is paramount in any printing environment.

Monthly Tasks: Performance and System Checks

- Light Output Measurement: Over time, LED emitters can degrade. Their light output might decrease. Use a radiometer to measure the UV irradiance. Compare this to the manufacturer’s specifications. If the output is significantly low, it might be time to consider LED head replacement. This ensures consistent curing quality.

- Component Integrity: Examine the entire unit for any signs of wear. Check wiring harnesses for fraying or damage. Inspect mounting hardware for tightness. Look for any unusual noises from the cooling system.

- Software and Controls: If your unit has a digital interface, check for any error messages. Ensure all controls are responsive. Firmware updates might be available. These can improve performance or fix bugs.

Annual or Bi-Annual Deep Dive: Professional Care

- Professional Servicing: Schedule a professional service check at least once a year. A trained technician can perform more in-depth diagnostics. They can check for internal component wear. They can also perform necessary recalibrations.

- Coolant Flush and Replacement: For water-cooled systems, flush and replace the coolant. Contaminated coolant can lead to corrosion and reduced cooling efficiency. Use the type of coolant specified by the manufacturer.

- Component Lifespan: LEDs have a finite lifespan, often measured in thousands of hours. While they degrade gradually, understanding their expected life is important. Plan for potential replacements. This avoids unexpected failures during a critical print run.

Optimizing for Long-Term Performance

- Proper Ventilation: Ensure the printing press area has adequate ventilation. This helps manage overall shop temperature. It also aids the LED unit’s cooling system.

- Environmental Control: Extreme temperatures can impact LED performance. Operate your curing units within the recommended environmental ranges.

- Ink and Coating Compatibility: Always use UV inks and coatings designed for LED curing. Different LED wavelengths require specific formulations. Using incompatible products will lead to poor curing and potential equipment damage. Consult your ink supplier.

- Operating Parameters: Do not run the LED units at maximum power continuously unless necessary. Running them at slightly lower power when full intensity isn’t needed can extend their operational life. Monitor your cure quality closely. Adjust power and speed settings as required.

Troubleshooting Common Issues

- Uneven Curing: This is often due to dirty lenses or degraded LEDs. It can also result from uneven substrate feeding. Check the lenses first. Then, consider measuring light output.

- Overheating: Insufficient cooling is the usual culprit. Check fans, filters, and coolant levels. Ensure the environment isn’t too hot.

- Flickering or Intermittent Output: This points to electrical issues. Check power connections and cables. If the problem persists, it might be an internal electronic fault.

By implementing these maintenance practices, you can significantly extend the life of your LED curing units. Consistent care leads to more reliable performance and better print quality for your narrow web flexo operations. It also contributes to a safer and more productive printing environment. Investing a little time in maintenance pays dividends in the long run.