Upgrading older flexo presses with UV curing systems isn’t just about keeping up with trends—it’s a practical move to boost productivity and print quality without scrapping existing equipment. For shops running narrow-web flexo or label presses, retrofitting UV can mean faster job turnarounds, reduced energy costs, and access to specialty inks. Let’s break down how to approach this without overcomplicating things.

Start by evaluating your press configuration. Older flexo models often lack the space or power infrastructure for UV systems. Measure the distance between print stations and dryer locations—LED UV lamps need specific mounting points without disrupting ink transfer or web tension. If you’re working with a 10-year-old press, check the electrical panel’s capacity. LED units draw less power than traditional mercury vapor lamps, but you’ll still need stable voltage to avoid flicker during runs.

Choosing between mercury arc and LED UV matters. While mercury systems handle thicker coatings, LED dominates in energy efficiency and instant on/off capabilities. For label converters printing sensitive substrates like thin films or heat-sensitive papers, LED’s cooler operation prevents material distortion. Pair this with low-odor UV inks, and you’ve got a setup that meets stricter VOC regulations without sacrificing adhesion.

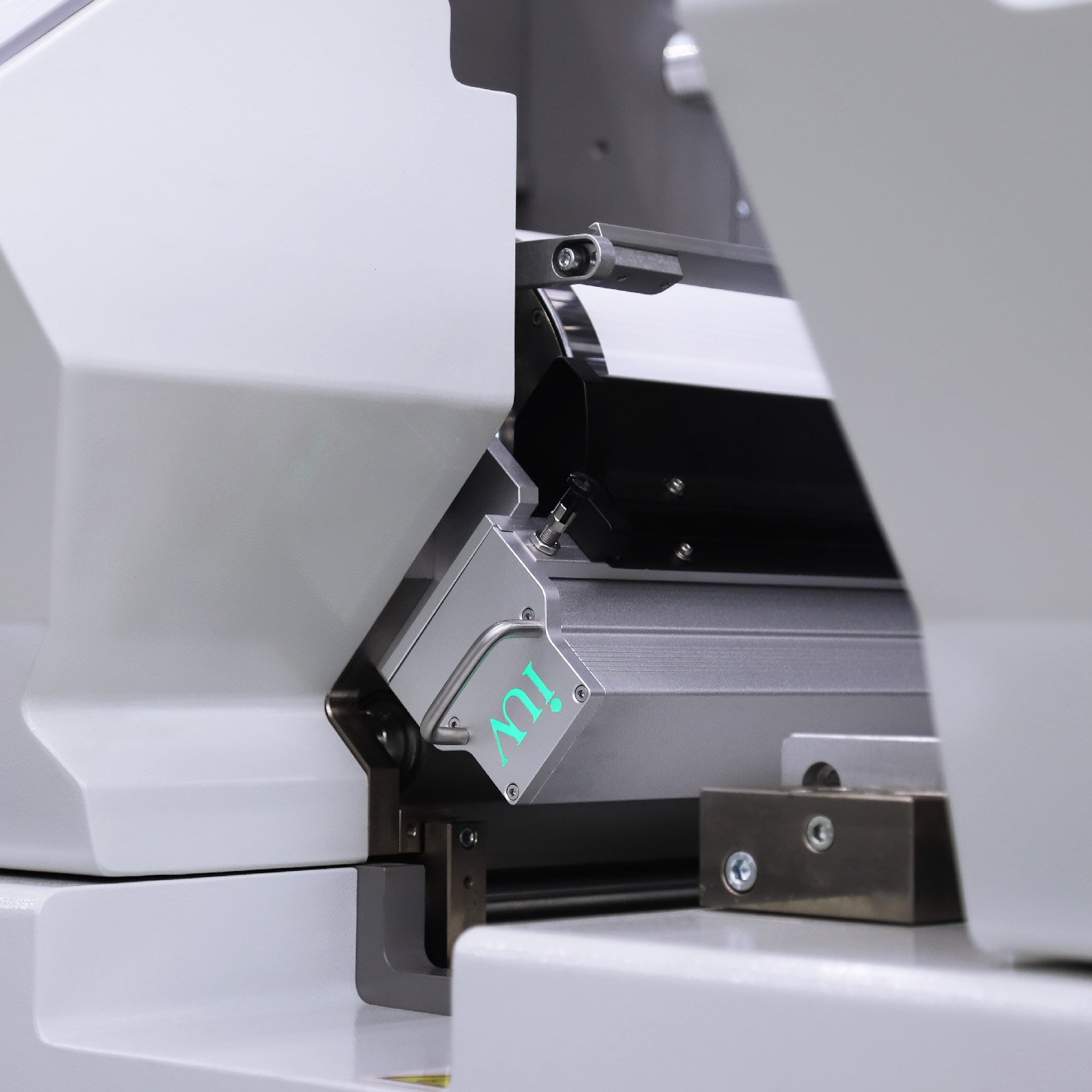

Retrofitting isn’t plug-and-play. You’ll need to integrate cooling systems to manage LED heat output—even at reduced temperatures, continuous operation demands airflow. Some shops retrofit auxiliary blowers between print units. Others opt for modular UV units that clamp onto existing press frames. One pro tip: Install quartz shields over lamps. They block ink mist contamination, which is critical when printing high-coverage graphics or white inks.

Ink compatibility can make or break the project. Not all UV inks cure equally under different wavelengths. Test formulations with your lamp’s spectral output—365-395nm LEDs work with most pigments, but metallic or fluorescent inks might require tailored settings. Work closely with ink suppliers to adjust photoinitiator levels. A common pitfall is under-curing at high speeds; use a simple thumb-smear test post-cure to check for tackiness before full production.

Web handling tweaks are non-negotiable. UV retrofits add weight to the press frame, potentially affecting registration. Rebalance dancer rollers and check tension controls. For hybrid setups mixing UV and water-based inks, consider interstation dryers to prevent ink contamination. One label printer saw a 40% speed boost by adding UV between flexo stations for spot varnish while keeping solvent-based colors—proof that partial retrofits can pay off.

Maintenance shifts post-retrofit. LED systems lack electrodes or gas fillings, but lenses still need weekly cleaning with IPA to maintain cure efficiency. Track lamp intensity with radiometers; most LEDs maintain 80% output for 10,000 hours. Keep spare lamps on hand, but avoid the temptation to “overcure” by ramping up power—it degrades components faster.

Cost recovery timelines vary. A mid-sized converter reported full ROI in 18 months through reduced energy bills and fewer substrate rejects. Factor in shorter web paths (no extended drying tunnels) and the ability to print on non-porous stocks like PET or metallic foils. For shops eyeing sustainable credentials, UV’s elimination of solvent emissions aligns with ESG reporting demands.

Still hesitant? Pilot a single print station. Many UV suppliers offer rental units for testing. Run a batch of pressure-sensitive labels or shrink sleeves—materials that traditionally require lamination or extended drying. If you nail the cure speed and adhesion, scale the retrofit incrementally. The goal isn’t to reinvent the press but to amplify its capabilities with targeted tech upgrades.

Future-proofing comes into play here. As regulatory pressures mount against traditional drying methods, UV-ready infrastructure keeps options open. Some systems now integrate IoT sensors for predictive maintenance, syncing with press controls to auto-adjust curing parameters mid-job. It’s not sci-fi—it’s about making existing gear smarter, one retrofit at a time.

Bottom line: Retrofitting flexo presses with UV isn’t a blanket solution, but a strategic play. Match lamp specs to substrate needs, engineer around spatial constraints, and lean on ink partners for formulation tweaks. Done right, you’ll turn legacy kit into a workhorse that handles today’s short runs and specialty jobs without missing a beat.