The packaging industry’s shift toward LED UV curing isn’t just a trend—it’s a revolution. From label printing to flexographic presses, manufacturers are ditching traditional mercury-vapor lamps for energy-efficient, precision-focused LED systems. Let’s unpack why this technology is dominating narrow-web, offset, and flexo workflows—and what it means for the future of sustainable packaging.

1. LED UV 101: Why It’s Reshaping Print Chemistry

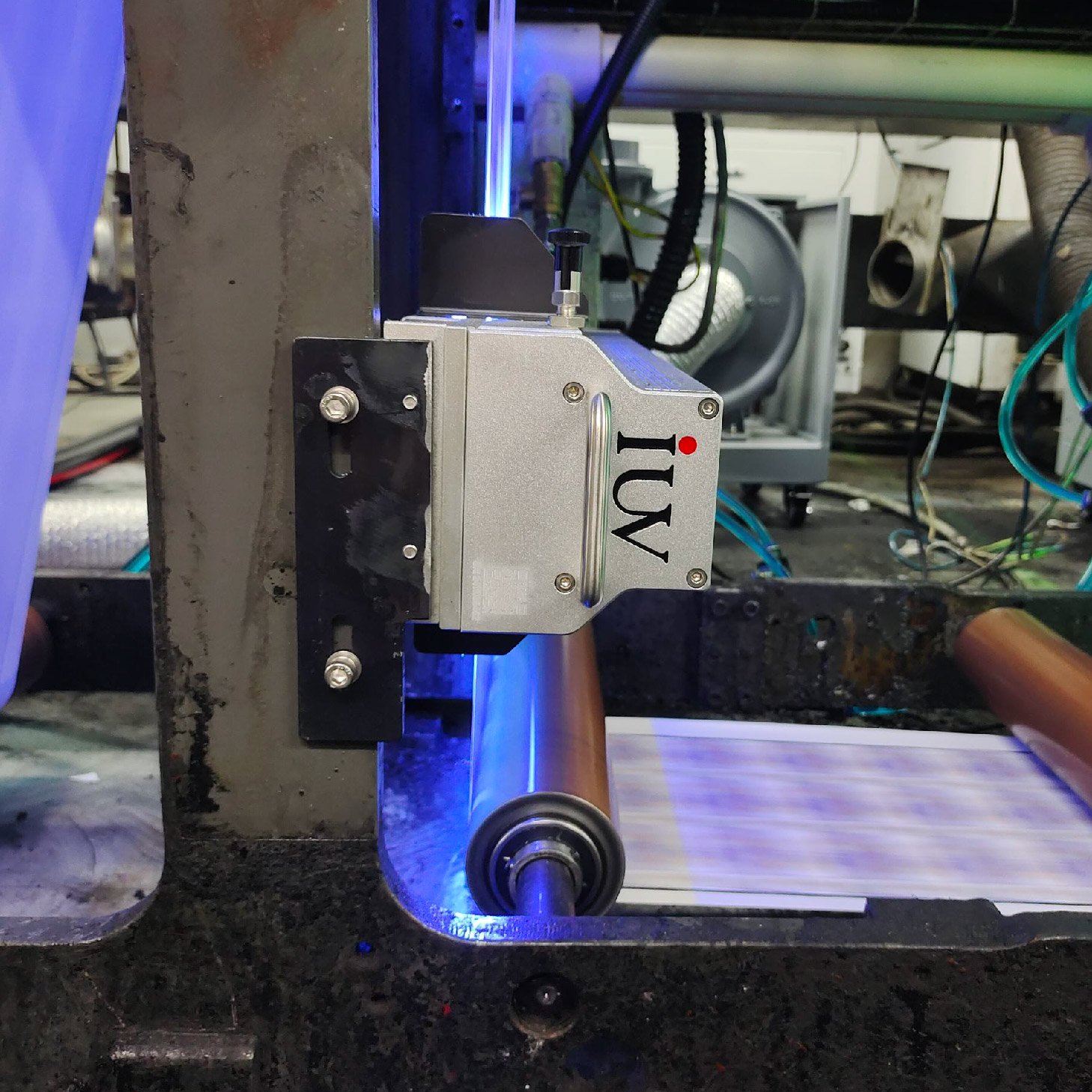

Traditional UV curing relies on mercury bulbs emitting broad-spectrum light to trigger ink polymerization. LED UV narrows this to specific wavelengths (365-405 nm), offering instant on/off capabilities and 70% less energy consumption. For packaging converters, this means:

- Faster curing: Substrate exits drier, reducing bottlenecks in inline finishing.

- Cooler operation: No heat distortion on thin films or heat-sensitive labels.

- Lower VOC emissions: No ozone production, aligning with EU’s Eco-Design Directive and California’s AB 1169.

2. Label Printing’s Silent Game-Changer

In pressure-sensitive label production, LED UV solves two headaches: static electricity on synthetic materials and ink adhesion on non-porous substrates. Esko’s 2023 study found LED-cured inks achieve 98% adhesion on PET and PP films vs. 82% with conventional UV. For wine labels or cosmetic sleeves, this means fewer rejects and brighter metallic/white ink layering.

3. Flexo’s Renaissance: LED UV in Narrow-Web Printing

Narrow-web flexo shops running UV inks saw a 40% productivity jump after switching to LED, per FTA data. The reason? No more lamp warm-up delays. A European converter reported 18-minute job changeovers (down from 35) by eliminating mercury bulb cooldown cycles. Plus, LED’s consistent irradiance prevents ink skinning on anilox rolls—a $7,000/year savings in roller maintenance for mid-sized shops.

4. Offset’s Quiet Pivot: Sheetfed Meets Sustainability

Heidelberg’s Speedmaster CX104 now offers LED UV as standard. Why? Instant curing lets sheetfed printers stack coated boxes immediately without anti-setoff powder. A Midwest packaging plant cut its polypropylene tray production time by 27% by pairing LED with low-migration inks—critical for FDA-compliant food packaging.

5. The ROI Math: Energy Bills Don’t Lie

LED UV systems draw 1.2 kW vs. 6 kW for mercury lamps. For a 3-shift operation:

- Annual energy savings: 6,570 kWh per press (enough to power 600 homes for a day).

- Bulb replacement costs: $0 (LED lifespan: 20,000 hours vs. 1,500 for mercury).

- HVAC savings: 30% lower AC load without mercury lamps’ infrared heat.