Boosting Profitability in Narrow Web Printing with LED UV Technology

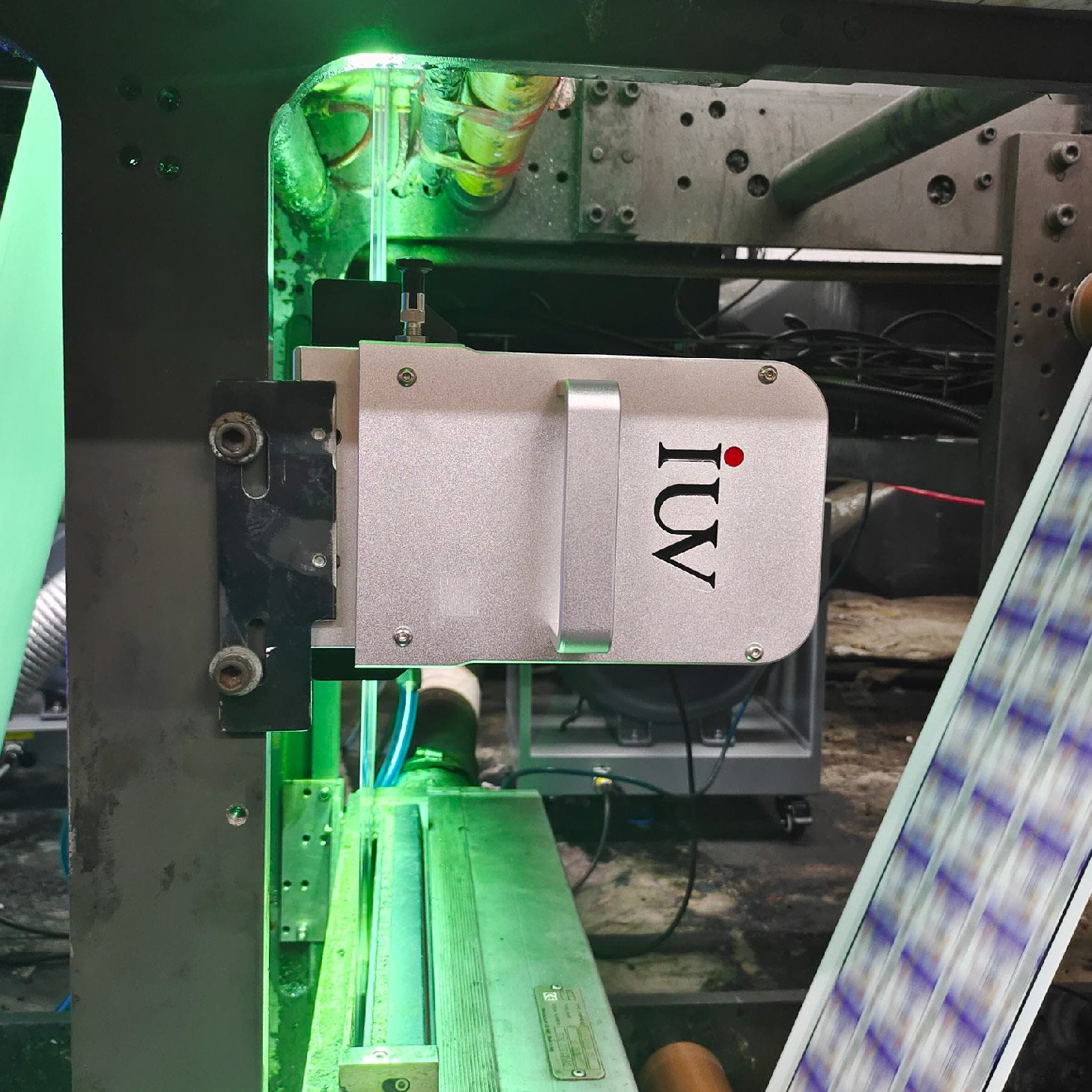

The narrow web printing industry thrives on speed, precision, and adaptability. Whether you’re producing labels, flexible packaging, or specialty decals, profitability hinges on minimizing downtime, reducing waste, and delivering consistent quality. Enter LED UV curing—a game-changing technology reshaping how printers approach jobs in flexo, offset, and hybrid setups. Let’s break down why this innovation isn’t just a trend but a profit multiplier.

1. LED UV 101: Faster Curing, Lower Costs

Traditional UV systems rely on mercury-vapor lamps, which require warm-up time, generate excess heat, and consume significant energy. LED UV curing eliminates these pain points by using targeted wavelengths to instantly polymerize inks and coatings.

- Energy Efficiency: LED systems use up to 70% less energy than conventional UV lamps. For a mid-sized narrow web press running 12-hour shifts, this translates to annual savings of $15,000–$20,000 on electricity alone.

- Zero Heat Emission: Delicate substrates like thin films or heat-sensitive labels? LED UV prevents distortion, reducing waste from scrapped materials.

- Instant On/Off: No warm-up delays. Start-stop jobs become viable without sacrificing productivity.

2. Flexo and Offset Printing: Where LED UV Shines

Label Printing

In label production, LED UV enables finer halftones and sharper text. Its rapid curing locks ink into place, reducing dot gain by up to 12% compared to traditional methods. This precision is gold for brands demanding photorealistic graphics on wine labels or cosmetic packaging.

Flexographic Applications

Flexo printers love LED UV for its ability to handle water-based inks and coatings without compromising drying speed. One converter reported a 30% increase in press speeds after switching to LED, citing fewer web breaks and reduced ink consumption.

Offset Hybrid Setups

Combining offset’s detail with LED UV’s efficiency unlocks new possibilities. A Canadian printer slashed makeready times by 40% using LED-curable offset inks for short-run premium packaging—proof that niche markets can drive big margins.

3. The Hidden Profit Levers

Reduced Maintenance Costs

Mercury lamps last ~1,500 hours; LED arrays exceed 20,000 hours. Fewer replacements mean lower labor costs and less production downtime.

Eco-Friendly = Customer-Friendly

LED UV contains no ozone-producing elements and works with VOC-free inks. Sustainability sells—72% of brand managers prioritize eco-conscious suppliers, per a 2023 FTA survey.

Ink Savings

Precise curing means less ink waste. One European converter cut ink usage by 18% while maintaining opacity, directly boosting their bottom line.

4. Real-World ROI: Case Studies

- Case A: A U.S. label printer upgraded two flexo presses with LED UV. Result: 22% faster job turnover, $28k/year energy savings, and a 15% uptick in premium clients seeking “greener” solutions.

- Case B: A narrow web offset shop in Germany reduced spoilage by 9% after adopting LED UV, citing fewer substrate rejects and better color consistency.

5. Implementing LED UV: Practical Tips

- Retrofit vs. New Presses: Retrofitting existing presses is cost-effective (ROI in 12–18 months), but new LED-equipped machines offer advanced controls.

- Ink Compatibility: Partner with suppliers offering LED-specific formulations. Not all UV inks work optimally under LED wavelengths.

- Staff Training: Quick-start guides and troubleshooting sessions prevent bottlenecks during the transition.

The Bottom Line

LED UV isn’t just about “going green” or keeping up with tech trends—it’s a strategic lever for profitability. Faster speeds, lower energy bills, and reduced waste create a ripple effect: happier clients, leaner operations, and a stronger competitive edge.

In an industry where razor-thin margins rule, LED UV curing is the upgrade that pays for itself. The question isn’t if to adopt it, but how fast you can integrate it into your workflow.