LED UV curing systems have transformed modern printing by offering rapid, energy-efficient, and eco-friendly curing solutions for inks and coatings. To maximize their performance, understanding their critical parameters is essential. This article breaks down the technical specifications and operational factors that define LED UV curing efficiency, quality, and sustainability in printing applications.

1. Wavelength Range: Precision for Effective Polymerization

LED UV systems emit light within a narrow wavelength spectrum, typically 365–405 nm, which activates photo-initiators in UV-sensitive inks and coatings. Selecting the correct wavelength is vital:

- 365 nm: Ideal for deep curing of thick or opaque layers.

- 385–405 nm: Preferred for surface curing and heat-sensitive substrates like films or plastics.

Mismatched wavelengths lead to incomplete curing or material damage. Unlike mercury lamps, LEDs eliminate ozone emissions and reduce heat generation, making them safer for delicate materials.

2. Irradiance and Energy Density: Balancing Speed and Quality

- Irradiance (W/cm²): Measures UV light intensity. High irradiance accelerates curing but risks overheating substrates. For example, heat-sensitive films require lower irradiance to prevent warping.

- Energy Density (J/cm²): Represents cumulative energy over time (irradiance × exposure time). Thick coatings demand higher energy density (e.g., 800 mJ/cm² vs. 200 mJ/cm²) to ensure full-depth polymerization.

Adjusting these parameters ensures optimal curing without compromising print quality. LED systems enable precise control, reducing energy waste compared to mercury lamps.

3. Power Density and Optical Power: Efficiency Metrics

- Power Density (W/cm): Calculated by dividing total lamp power by curing width. This ensures uniform UV exposure across substrates, critical for large-format printing.

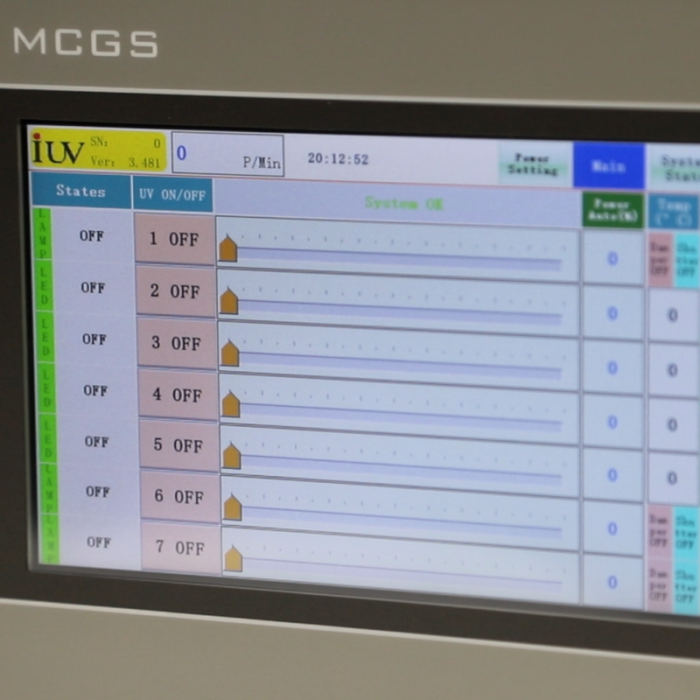

- Optical Power (mW/cm²): Directly impacts curing effectiveness. Insufficient power causes under-curing, while excess power degrades materials. Advanced LED systems, like the FC-L200, allow real-time adjustments via touchscreens for tailored outputs9.

4. Cooling Systems: Sustaining Performance and Longevity

LEDs generate less heat than mercury lamps, but effective cooling remains crucial:

- Air Cooling: Suitable for low-to-medium heat loads17.

- Liquid Cooling: Essential for high-intensity systems, maintaining temperatures below 60°C to protect heat-sensitive substrates79.

For instance, IST METZ’s BLK S system uses water-cooled reflectors and air cooling to enhance efficiency by 70%7.

5. Curing Speed and Duty Cycle: Synchronizing Throughput

- Curing Speed (m/min): Must align with irradiance and substrate type. High-speed presses (e.g., 9,000 sheets/hour) require optimized LED intensity to avoid bottlenecks.

- Duty Cycle: Controls LED pulsing to manage heat. Adjusting the on-off ratio prevents overheating while maintaining productivity.

LEDs’ instant on/off capability eliminates warm-up delays, boosting production efficiency by 20–30%.

6. Beam Width and Uniformity: Ensuring Consistent Curing

- The UV beam must match the substrate width to avoid under-cured edges. Precise alignment and reflector design (e.g., IST METZ’s FSP system) ensure uniform light distribution79. Narrow web presses often use modular LED arrays to adjust beam width dynamically.

7. Advanced Monitoring and Control

Modern systems integrate IoT-enabled sensors for:

- Real-Time UV Measurement: Tools like the UMS-2 monitor irradiance and energy density to maintain consistency7.

- Predictive Maintenance: Detecting voltage drops or LED degradation minimizes downtime. The FC-L200 system offers multilingual touchscreens for real-time status updates9.

Advantages of Optimized LED UV Curing

- Eco-Friendly: Eliminates VOCs and mercury, reducing environmental impact.

- Energy Savings: Consumes 65% less energy than mercury lamps, with lifespans exceeding 20,000 hours.

- Material Versatility: Enables printing on heat-sensitive substrates like PET and thin films.

- Faster Turnaround: Instant curing allows immediate post-processing, reducing production cycles.

Conclusion

Mastering parameters like wavelength, irradiance, cooling, and beam uniformity empowers printers to achieve high-quality results while embracing sustainable practices. As LED UV technology evolves, innovations in modular design and smart controls (e.g., Heidelberg’s DryStar systems) continue to redefine printing efficiency.