The printing industry is at the forefront of a technological revolution, transitioning from the traditional mercury curing systems to the modern, energy-efficient LED alternatives. This shift is not only a response to the need for more sustainable practices but also a stride towards higher efficiency and performance in print technology.

The Mercury Curing Paradigm

Mercury curing systems, utilizing arc lamps, have been the industry standard for UV curing due to their ability to produce a broad spectrum of high-intensity UV light.

However, these systems are energy-intensive and generate a significant amount of heat, requiring substantial cooling solutions.

The use of mercury also poses environmental challenges, with strict regulations governing their disposal.

- Energy Consumption: Mercury lamps consume a high amount of power, leading to increased operational costs.

- Thermal Management: The heat generated necessitates additional cooling, further adding to energy usage.

- Environmental Impact: Mercury is a hazardous substance, making the disposal of spent lamps a significant environmental concern.

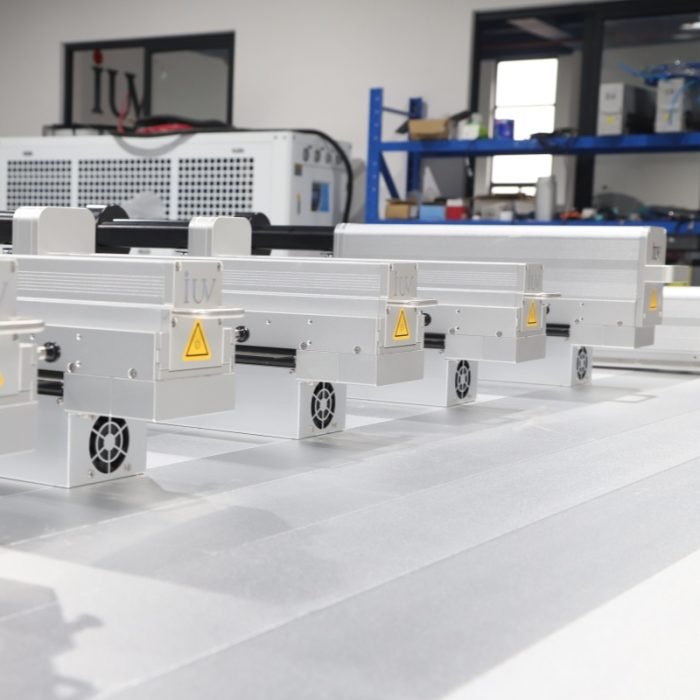

The LED Curing Advancement

LED curing systems have emerged as a viable and superior alternative, offering numerous advantages over mercury systems:

- Energy Efficiency: LEDs consume less power for equivalent light output, reducing energy consumption.

- Heat Emission: They generate minimal heat, eliminating the need for extensive cooling and resulting in a more energy-efficient process.

- Longevity: LEDs have a longer operational life, reducing replacement frequency and related costs.

- Instantaneous Operation: Unlike mercury lamps, LEDs achieve full light output instantly, improving production efficiency.

- Spectral Control: LEDs allow for precise control over the UV spectrum, optimizing the curing process for various ink and coating types.

Technical Analysis

- Spectral Output: Mercury lamps emit a broad spectrum of light, including UV, visible, and IR light. In contrast, LEDs can be tailored to emit specific UV wavelengths, improving curing efficiency and reducing energy waste on unwanted light types.

- Power Supply Requirements: LED systems typically require lower voltage and have simpler power supply needs compared to the high-voltage starters and ballasts required for mercury lamps.

- Controllability: LED arrays can be modulated to adjust intensity and wavelength in real-time, offering superior control over the curing process.

Technical Analysis

The transition to LED curing systems is not only beneficial from an operational standpoint but also from an environmental and economic perspective:

- Reduced Carbon Footprint: Lower energy consumption directly translates to reduced CO2 emissions.

- Cost-Effectiveness: The initial investment in LED systems is often offset by the savings in energy and maintenance costs over time.

Implementation Challenges and Solutions

Transitioning from mercury to LED curing systems requires consideration of existing equipment compatibility and the specific curing requirements of the printing process.

IUV, as a leading manufacturer of UV and LED curing equipment, offers modular and intelligent design solutions that can be tailored to various printing press types, ensuring a seamless transition.

Future Outlook