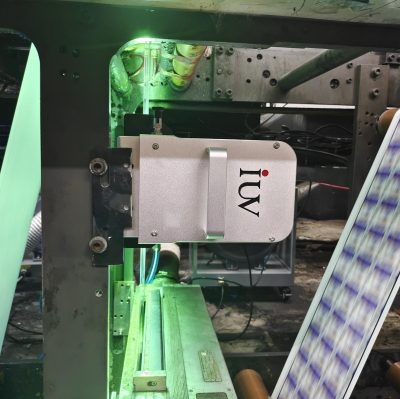

IUV Hybrid UV Curing System Showing At Nilpeter India Chennai Factory Showroom

In the ever-evolving world of printing technology, the quest for innovation and efficiency continues to drive the industry forward. At IUV, we are committed to leading this charge by providing cutting-edge solutions that not only enhance performance but also align with the growing demand for sustainability. Today, we are excited to announce the installation and demonstration of our IUV Hybrid UV curing system at the Nilpeter India Chennai Factory.

The Nilpeter India Chennai Factory: A Hub of Innovation

The Nilpeter India Chennai Factory is a beacon of innovation in the printing industry. Known for its commitment to quality and efficiency, the factory is the ideal location to showcase the capabilities of the IUV Hybrid UV curing system. The installation of this state-of-the-art system marks a significant milestone in the factory’s journey towards adopting the latest UV technologies to enhance its operations.

The installation of the IUV Hybrid UV curing system at the Nilpeter India Chennai Factory is not just about showcasing the latest technology; it’s also about providing valuable training and support to the factory’s team. Our experts will be on hand to demonstrate the system’s capabilities and provide comprehensive training to ensure that the factory’s staff can make the most of this advanced technology.

The IUV Hybrid UV Curing System: A Game-Changer

The IUV Hybrid UV curing system represents a significant leap forward in UV curing technology. This advanced system combines the best of both worlds—mercury and LED UV technologies—to offer unparalleled flexibility, efficiency, and performance. Designed to meet the diverse needs of modern printing operations, it provides the perfect solution for a wide range of applications.

Key Features of the IUV Hybrid UV Curing System

-

Dual Technology Integration: The system seamlessly switches between mercury and LED UV curing, allowing for optimal process optimization for different materials and inks. This flexibility ensures that every print job is handled with precision and efficiency.

-

Energieffektivitetsövervägande: The LED UV option significantly reduces energy consumption, leading to lower operational costs and a reduced environmental footprint. This aligns perfectly with the growing focus on sustainability in the printing industry.

-

High-Quality Curing: Consistent and high-quality curing is guaranteed across various substrates, maintaining the integrity and appearance of prints. This ensures that every product meets the highest standards of quality.

-

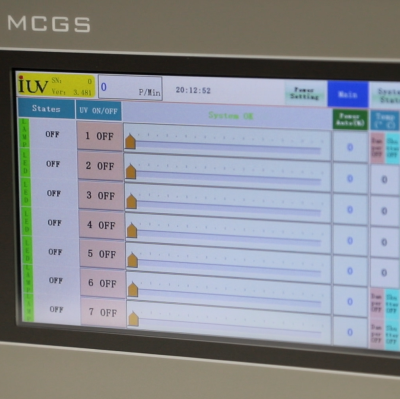

Smart Control System: Advanced controls and monitoring capabilities allow for precise management of the curing process, enhancing productivity and reducing downtime. This smart system ensures that every aspect of the curing process is optimized for maximum efficiency.

Future Outlook