In the industry of printing, coating, and other material processing industries, UV curing plays a pivotal role in achieving high-quality finishes with optimal efficiency. The introduction of LED UV curing technology has revolutionized the way industries approach curing, providing superior energy efficiency, longer lifespan, and better control over the curing process compared to traditional mercury-based UV lamps.

However, as industries continue to demand faster, more efficient, and flexible production processes, there is a growing need to enhance the performance of LED UV systems further. One of the most significant advancements to meet these demands is the IUV’s automatic sensor with an owned patent.

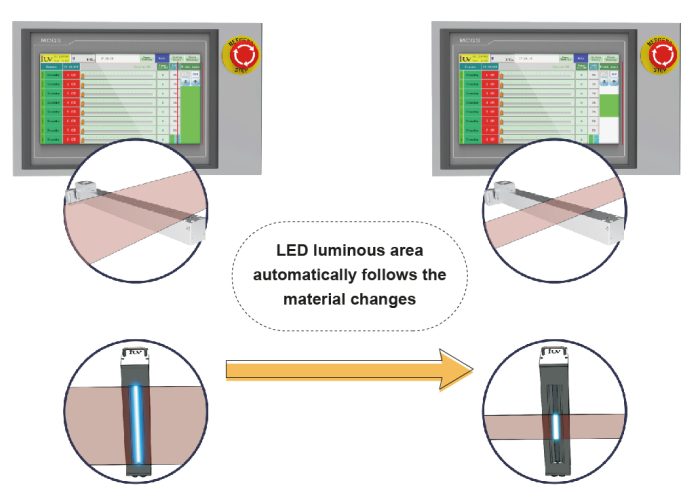

The primary function of an automatic width measurement sensor is to constantly monitor the width of the material being processed, whether it’s paper, film, or any other substrate. Since many production lines involve varying material sizes or widths.

This tech helps automatically adjust the curing zone to fit the exact width of the material, ensuring that the energy is efficiently used and the curing quality is maintained across the entire production line.

Without an automatic sensor, the curing system would either waste energy or fail to cure the material uniformly. For instance:

Over-curing: If the UV light zone is fixed and too wide, it might over-cure areas where no material is present, wasting energy and potentially harming the environment.

Under-curing: If the light zone is too narrow, the material could be under-cured, leading to poor adhesion, incomplete curing, or even product defects.

One of the significant advantages of LED UV curing systems is their high energy efficiency compared to traditional UV curing methods. However, even with LED technology, inefficiencies can arise if the curing area is too large for the material being processed.

By integrating an automatic sensor, the LED UV system can adjust the curing zone to the exact material width, avoiding the need to cure areas that do not require UV treatment. This results in:

Reduced energy consumption, as the LED lights are only active in the regions where curing is needed.Lower operating costs, as unnecessary energy expenditure is minimized.

In essence, this level of precision makes the entire curing process more sustainable, providing both environmental and economic benefits.

Consistency in print quality is a critical factor in industries such as packaging, labeling, and graphic arts. Variations in curing levels can lead to a range of issues, including poor adhesion, inconsistent gloss, or even visible defects. If the material width is not measured and adjusted in real-time, areas outside the material may receive UV exposure, potentially leading to uneven curing.

IUV’s automatic sensor, the curing zone is precisely aligned with the material, ensuring that every part of the material receives uniform curing. This precision guarantees:

Better quality control with more consistent output.

Reduced chances of product defects related to uneven curing.Fewer reworks and less waste, contributing to a higher yield per production cycle.

In today’s fast-paced manufacturing environment, production lines are expected to handle a variety of materials in different sizes, without slowing down or requiring frequent manual adjustments. Traditionally, changing the curing area for different material widths would require time-consuming manual interventions, which slows down the entire process.

IUV’s automatic sensor offers the flexibility to quickly adapt the curing area to different material widths without any downtime or manual recalibration.