Research and Development Capabilities

A professional manufacturer should demonstrate a strong commitment to research and development. Look for companies with dedicated R&D teams working on improving existing technologies and developing new solutions. Manufacturers who invest in innovation are more likely to offer systems with advanced features and better performance.

Technical Knowledge and Experience

Evaluate the manufacturer’s technical expertise in UV curing technology. They should have a deep understanding of photopolymerization processes, UV light properties, and material science. The team should include engineers and scientists with specialized knowledge in UV curing applications.

Patent Portfolio and Intellectual Property

A manufacturer with a substantial patent portfolio demonstrates technical leadership and innovation. These patents often translate into unique advantages in their products, such as improved curing efficiency, enhanced safety features, or expanded substrate compatibility.

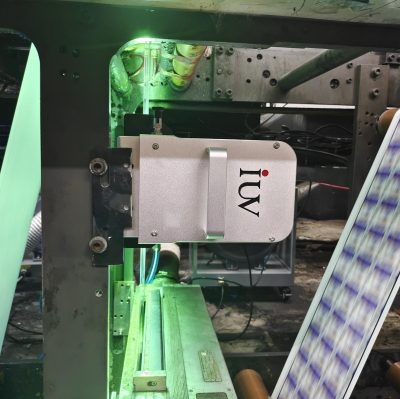

Build Quality and Durability

Examine the physical construction of the UV curing systems. High-quality components, robust build materials, and precise manufacturing tolerances indicate a professional approach to product development. The system should be designed to withstand demanding industrial environments.

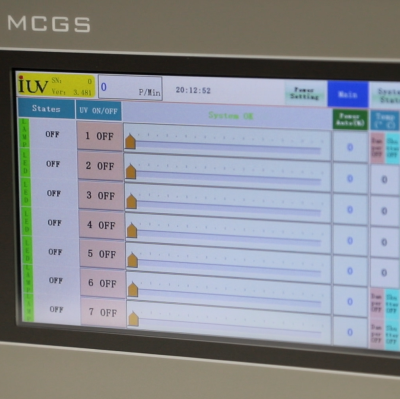

Performance Specifications

Compare technical specifications across manufacturers, including UV intensity, wavelength options, curing speed, and energy efficiency. Professional systems will offer consistent performance across these metrics, with documentation to support their claims.

Testing and Certification

Professional manufacturers subject their products to rigorous testing and obtain relevant certifications. Look for systems that have been tested for safety, performance, and reliability. Certifications from recognized standards organizations add credibility to the manufacturer’s claims.

Customization Capabilities

A professional manufacturer should be able to customize systems to meet specific application requirements. This includes adapting to various substrate sizes, shapes, and materials, as well as integrating with existing production lines.

Industry-Specific Experience

Evaluate the manufacturer’s experience in your specific industry sector. Different applications—such as printing, electronics manufacturing, woodworking, or medical device production—have unique requirements. A manufacturer with proven success in your field will better understand your specific needs.

Application Engineering Support

The manufacturer should provide application engineering support to help optimize system performance for your specific use case. This includes advice on system configuration, operating parameters, and troubleshooting.

Pre-Sales Support

Professional manufacturers offer comprehensive pre-sales support, including technical consultations, demonstrations, and testing of their systems with your specific materials. They should be responsive to inquiries and provide clear, detailed information about their products.

Training and Documentation

Look for manufacturers who provide thorough training programs and comprehensive documentation. This includes operator manuals, maintenance guides, and safety protocols. Well-documented systems are easier to operate and maintain.

After-Sales Service

Evaluate the manufacturer’s service offerings, including warranty terms, repair services, and spare parts availability. A professional manufacturer will stand behind their products with reliable support and quick response times to service requests.

Market Presence and History

Consider the manufacturer’s length of time in business and their market reputation. Established companies with a long history in the UV curing industry often have more refined processes and proven track records.

Customer References and Case Studies

Request customer references and review case studies demonstrating the manufacturer’s systems in real-world applications. Professional manufacturers will be willing to connect you with satisfied customers who can share their experiences.

Industry Recognition and Awards

Recognitions, awards, and industry certifications indicate a manufacturer’s standing within the professional community. These accolades often reflect innovation, quality, and customer satisfaction.

Environmental Impact

Evaluate the manufacturer’s commitment to environmental sustainability. This includes the environmental footprint of their production processes, as well as the eco-friendliness of their products. Look for systems with low energy consumption, minimal emissions, and recyclable components.

Safety Standards

Professional manufacturers adhere to strict safety standards in both their production facilities and their products. Their systems should include safety features such as emergency stop functions, protective shielding, and compliance with relevant safety regulations.

Total Cost of Ownership

Consider not just the initial purchase price but the total cost of ownership over the system’s lifespan. This includes energy consumption, maintenance costs, consumable expenses, and potential downtime.

Return on Investment

Evaluate the manufacturer’s claims regarding ROI, including increased production efficiency, reduced waste, and improved product quality. A professional manufacturer should be able to provide data supporting these benefits.

Value-Added Services

Look for additional services that enhance the overall value proposition, such as financing options, leasing arrangements, or trade-in programs. These can make professional-grade systems more accessible for businesses with varying budget constraints.