Ensuring the curing quality of UV ink is crucial. Three key factors are:

-

Ink Balance

Controlling the ink balance during printing is important to prevent emulsification, which can reduce UV light transmittance and slow curing. Maintaining a small water volume helps ensure bright colors, thick ink layers, and clear dots.

-

Temperature and Humidity

Appropriate workshop temperature (20-26°C) and humidity (50-65% relative humidity) are essential for optimal UV ink performance and curing.

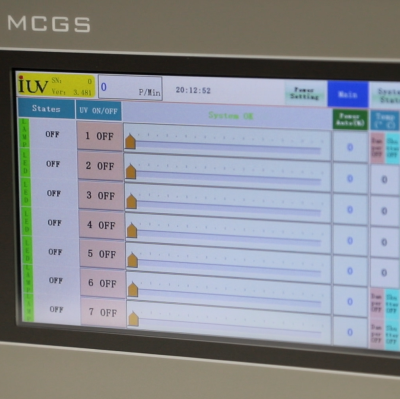

- UV Light Intensity

Selecting and maintaining UV lamps with appropriate power, keeping them clean, and ensuring proper reflector function are crucial for providing sufficient UV light intensity for complete ink curing.

Color cross-over is a common issue in UV ink printing, often caused by improper color sequence or excessive ink fluidity. To address this:

-

Instant Curing and High Production Efficiency

LED UV curing enables instant curing, facilitating high production efficiency and broad adaptability to various substrates and printing conditions.

-

Superior Physical and Chemical Properties

UV-printed materials exhibit excellent physical and chemical properties, ensuring durability and longevity.

Insufficient adhesion of UV ink to non-absorbent substrates like metallic cardboard can be addressed by:

-

Corona Treatment

Treating the printing material with corona discharge changes its polarity and increases the binding ability of UV ink, improving adhesion.

-

Adhesion Promoters

Communicating with ink suppliers and adding appropriate adhesion promoters to the UV ink can enhance its adhesion to substrates.

-

Ensuring Proper Curing

Communicating with UV curing system suppliers, verifying and optimizing the UV ink curing process is crucial, as proper curing directly affects adhesion.

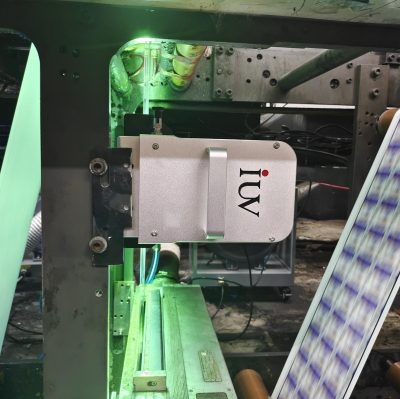

Applying UV inks requires specialized printing equipment due to their unique properties:

-

Rubber Rollers and Blankets

Dedicated UV-resistant rollers and blankets are necessary to prevent expansion or cracking.

-

Paper Grippers

UV-resistant grippers prevent deformation from UV exposure, ensuring accurate overprinting.

-

Ink Fountain Sheets

Reliable, UV-resistant ink fountain sheets prevent cracking and ink leakage into mechanisms.

-

Maintenance

Regular cleaning and maintenance of equipment, using qualified accessories and raw materials.

Proper storage conditions are essential for maintaining UV ink quality and performance:

温度

Humidity

Sealed Storage

Shelf Life

Various factors that affect the use of UV ink are closely connected and influence each other. Printing companies must consider multiple perspectives in the process of applying UV ink, eliminate difficult problems, and give full play to the advantages of UV ink.

Addressing challenges in UV ink printing requires a comprehensive approach, considering factors such as ink curing, color management, adhesion, equipment suitability, and proper storage conditions. By following best practices and addressing potential issues proactively, printing companies can leverage the benefits of UV inks while ensuring optimal printing quality and efficiency.

- Ensure proper curing by controlling ink balance, temperature, humidity, and UV light intensity.

- Prevent color cross-over by arranging color sequence and adjusting printing pressure.

- Improve adhesion through corona treatment, adhesion promoters, and proper curing.

- Use specialized UV-resistant equipment, including rollers, blankets, grippers, and ink fountain sheets.

- Maintain optimal storage conditions for UV inks, including temperature, humidity, sealed containers, and shelf life management.

- Address challenges comprehensively, considering all factors affecting UV ink performance.

- Use advancing UV LED